Focus Sifter Machine Production

It is the common testing instruments in laboratory, and also a special equipment for testing particle size of test sieve.

Screening accuracy: 5μm

Vibration frequency: 3000 times/min

Screen diameter: 400/300/200/100/75mm

Can put screen: 1-8 layers

Various optional specifications with customization

Key Points: High precision, timer function,small body, smooth running

Electric Sieve Shaker is a precision instrument for particle separation and size determination. It can sieve powders, liquids, and sieve materials up to 5um. It is widely used in laboratories and quality inspection departments for particle size distribution, impurity level, solid It can be placed in 1-7 layers of test sieves, which can accurately separate a granular material into 2-7 particle size segments at the same time, install a time relay, and set the sieving time to reduce the detection error to Minimum, to ensure accurate judgment of product quality.

Electromagnetic vibration, the frequency reaches 3000 rpm, and the high frequency up and down vibration can reduce the clogging of the screen and make the material unloading fast.

The sieve frame, vibrating plate and box of the electromagnetic test sieve are all made of SUS304 stainless steel with a wall thickness of 0.6mm, non-magnetic and durable.

The dry sieve can be sieved to 20 microns (625 mesh), and the negative pressure device can be added to sieve to 5 microns to solve the problem of dry sieving of ultra-fine powder.

The sieve machine can be placed with 8 layers of test sieves (including the sieve bottom), which can precisely separate a granular material into 2-7 particle segments at the same time

Equipped with time relay control, it can be automatically shut down at regular intervals to ensure test repeatability

Electric Sieve Shaker can be dry sieved to 5 microns, and can be used for particle size detection and size analysis of powders, granules, liquids and other materials. The specific materials include flour, metal powder, abrasives, quartz sand, soil, mineral powder, traditional Chinese medicine powder, pearl powder Wait

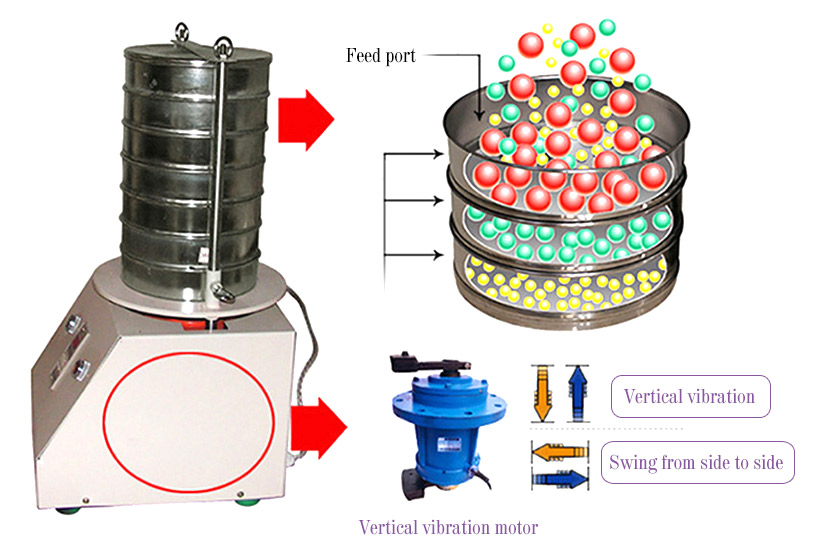

Electric Sieve Shaker uses electromagnetic vibrator as the vibration source. The vibration of the electromagnetic vibrator drives the low-sit vibration of the sieve machine, and then transmits it to a set of standard test sieves arranged on the base from coarse to fine through the bottom seat, and vibrates up and down with high frequency. At the same time, the vibration motor (or reciprocating mechanism) installed in the lower part spreads the material. The material vibrates on the screen surface of the standard inspection sieve, so that the material particles smaller than the mesh size of the test sieve surface are sieved into the lower test sieve, and the layers are screened in this way, so that only materials of the same particle size are left in each layer of the test sieve to achieve different particle size. Separate and determine the particle size composition of this material.

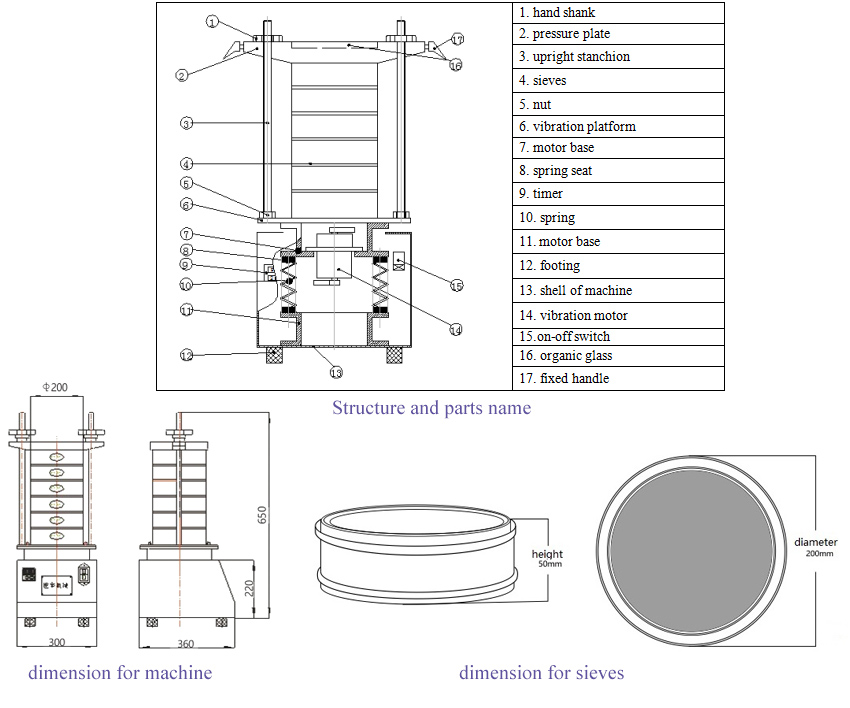

Electric Sieve Shaker consists of handle, pressure plate, sieve cover, sieve frame, sieve bottom, tray, isometric adjustment rod, time relay, vibration motor, etc.

Dahan Electric Sieve Shaker manufacturer sells Electric Sieve Shaker machine, electromagnetic test vibrating screen machine, electromagnetic vibrating screen, electromagnetic inspection screen, electromagnetic standard test screen, electromagnetic screen and other products, complete models and specifications, prices as low as 200 yuan, can be used for materials The dry and wet separation and particle size detection are suitable for ultra-fine powder materials for male screening. According to different materials, manufacturers also provide special customized products.