Focus Sifter Machine Production

Vibrating Sieve is a common equipment for classifying and removing impurities such as small particles, mucus, powder and other materials.

Feed particle size: < 10 mm

Feed particle size: 80-600 mesh

Number of layers: 1 - 5 layers

Material: Stainless Steel, Carbon Steel, Plastic

Material: powder (starch, flour, milk powder, rubber powder, copper powder, traditional Chinese medicine powder, resin powder, heavy calcium carbonate), granule (corn, soybean, quartz sand, kaolin), liquid (soybean milk, juice, soy sauce, mud, waste oil, waste water, dyeing and finishing waste water)

Vibrating Sieve sieves powder, granular and slurry materials, no matter whether the material is dry or wet, fine or rough, heavy or light, 0-400 mesh can be screened, whether it is liquid or slurry 0-600 mesh can be filtered. From the material, it can be divided into standard type Vibrating Sieve and all stainless steel Vibrating Sieve. The standard type and material base part are made of 304 stainless steel, the base is made of carbon steel, and all stainless steel is made of 304 stainless steel for the cylinder body. It is used in industries with strict hygiene requirements such as food and medicine. For corrosive materials such as strong acidity and alkalinity, we have designed a corrosion-resistant vibrating screen - plastic Vibrating Sieve, which can ensure that the material will not deteriorate.

vibrating sieve for pharma

vibrating sieve for milk processing

vibrating sieve for fruit juice

Chemical industry: resins, coatings, industrial drugs, cosmetics, paints, traditional Chinese medicine powder, etc.

Food industry: powdered sugar, starch, salt, rice flour, milk powder, soy milk, egg powder, soy sauce, fruit juice, etc.

Metal, metallurgy and mining: aluminum powder, lead powder, copper powder, ore, alloy powder, electrode powder, manganese dioxide, electrolytic copper powder, electromagnetic material, grinding powder, refractory material, kaolin, lime, alumina, heavy carbonic acid Calcium, quartz sand, etc.

Pollution treatment: waste oil, waste water, dyeing and finishing waste water, auxiliaries, activated carbon, etc.

High efficiency, compact and durable design, sorting and sieving of mucus.

The mesh is not blocked, the powder is not flying, and it can be sieved to 500 mesh or 0.028mm.

The screen height can reach 4 layers, and a material can be sorted into 2-5 different particle size specifications.

Impurities and coarse materials are automatically discharged, and continuous operation is possible.

The design of the separate mesh frame between the mother and the child, the screen mesh can be used for a long time, and the mesh is changed quickly, only 3-5 minutes.

High frequency electric is generated by ultrasonic vibration sieve source through the transducer into longitudinal oscillation of high frequency sine form,those sasser spread to reasonator,and generate resonance,then vibration evenly transmitted to the screen surface by the resonator.Raw material doing low-frequency Three-D vibration,while ultrasonic vibrations,can prevent clogging screen mesh,but also improve the capacity and accuracy of screening.

| model | Sieve Diameter (mm) | Power (kw) | Grain size (mm) | Voltage (V) | Price ($/unit) |

| DH-400 | 350 | 0.18 | <10 | 380 | $400.00-$550.00 |

| DH-600 | 550 | 0.25 | $584.00-$830.00 | ||

| DH-800 | 750 | 0.55 | $690.00-$1,000.00 | ||

| DH-1000 | 920 | 0.75 | $970.00-$1,40000 | ||

| DH-1200 | 1120 | 1.1 | $1,300.00-$1,900.00 | ||

| DH-1500 | 1420 | 1.5 | $1,800.00-$2,600.00 | ||

| DH-1800 | 1720 | 2.2 | $2,300.00-$3,700.00 |

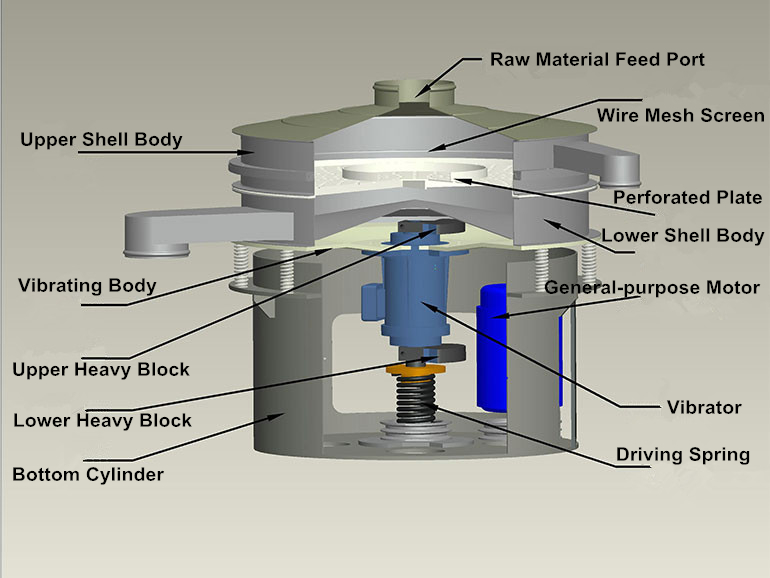

Vibrating Sieve consists of vibrating motor, screen, cleaning device, seal, damping spring, inlet and outlet, etc.

1. Vibration motor: YZUL series vertical vibration motor single-flange structure is adopted, which is convenient for installation and maintenance, which reduces the weight of the host, reduces the cost of the host, and enables the host to handle more materials.

2. Screen: The appropriate mesh can be selected according to the screening requirements. There are three materials of carbon steel, stainless steel and nylon screen.

3. Net cleaning device: rubber balls or silicone balls are commonly used. Rubber balls are mainly used in occasions where the environmental sanitation requirements of materials are not very strict, and the cost is also low. Silicone balls have good elasticity and no pollution. They are mainly used in food, medicine and other industries, and the cost is relatively high.

4. Seals: prevent the leakage of raw material fluid or solid particles from adjacent joint surfaces, prevent external impurities such as dust and moisture from invading the components and materials inside the machine and equipment, and reduce the destructive force of the vibrating screen to the screen frame during vibration.

5. Shock-absorbing spring: Mechanical parts that use elasticity to work, connect the screen body and the base, play a buffering role in the working process of the vibrating screen, isolate noise and prolong the service life of the machine.