Focus Sifter Machine Production

Screen size: 2-500 mesh

Output: 1-5 tons/hour

Product features: powder does not fly, liquid does not leak, does not block the net, automatic discharge, a variety of materials, 1-5 layers optional

Material: carbon steel, stainless steel (for food and pharmaceutical industries), plastic (resistant to strong acid, strong alkali corrosion)

Model: Diameter 400mm-1800mm

Customization: ordinary type, gate type (to control the material screening time), edge type (to prevent liquid material from splashing), ultrasonic type (to prevent material agglomeration from clogging)

Applicable materials: starch, soy milk, soy sauce, monosodium glutamate, resin powder, paint, traditional Chinese medicine powder, electromagnetic materials, plastic granules and other powder, granule or slurry materials

Vibro sifter machine is an equipment for screening powder, granule and liquid material, removing impurities and filtering. Carbon steel, stainless steel, plastic; according to the needs of special industries, it can be designed as gate type vibro sifter machine, edged type vibro sifter machine, explosion-proof vibro sifter machine and other models.

Classification and screening: The solid particles are divided into different particle groups of equal size, and a single rotary vibrating screen can accurately and continuously classify 2-6 particle segments at the same time. It is suitable for the classification of granular and powdery materials in many industries.

Screening impurities: Quickly remove large and small particles with a low percentage.

Solid-liquid separation: It can quickly remove insoluble substances in various types of slurries. It can filter up to 100 cubic meters per hour. It is suitable for filtration of liquids such as ceramics and pigments.

Chemical industry: resins, coatings, industrial medicines, pigments, paints, traditional Chinese medicine powder, etc.

Food industry: powdered sugar, starch, salt, rice flour, milk powder, soy milk, egg powder, soy sauce, fruit juice, etc.

Metal, metallurgy and mining: aluminum powder, lead powder, copper powder, ore, alloy powder, electrode powder, manganese dioxide, electrolytic copper powder, electromagnetic material, grinding powder, refractory material, kaolin, lime, alumina, heavy carbonic acid Calcium, quartz sand, etc.

Pollution treatment: waste oil, waste water, dyeing and finishing waste water, auxiliaries, activated carbon, etc.

1. It can meet various powder and particle screening requirements and liquid filtration requirements. The screening can be as fine as 500 mesh or 0.028mm, and the liquid material can be filtered to 5 microns.

2. A bouncing and cleaning device is installed under the screen of each layer. By continuously hitting the screen, the material can be screened smoothly and effectively avoid the problem of material blocking the screen.

3. Impurities and coarse materials are automatically discharged, continuous operation is possible, and the output can reach 5 tons/hour

4. 1-5 layers of multi-layer screening can obtain 2-6 kinds of finished products of different specifications.

5. Fully sealed structure, no powder overflow, the discharge port can be rotated 360°, and it only takes 3-5 minutes to replace the screen.

The Vibro sifter machine uses a vertical vibration motor as the excitation source. The eccentric weights at the upper and lower ends of the vibration motor convert the rotary motion into horizontal, vertical and inclined three-dimensional motion, and transmit it to the screen surface of the rotary vibrating screen. The feeding port enters the equipment. According to different screening requirements, the material passes through 1-5 layers of sieves with different mesh numbers. During this process, the net cleaning devices located under the sieves of each layer keep hitting the screen. The material can be screened smoothly and effectively avoid the problem of material blocking. Discharge, for the sieve, to complete the purpose of screening or filtration.

| model | Sieve Diameter (mm) | Power (kw) | Grain size (mm) | Voltage (V) | Price ($/unit) |

| DH-400 | 350 | 0.18 | <10 | 380 | $400.00-$550.00 |

| DH-600 | 550 | 0.25 | $584.00-$830.00 | ||

| DH-800 | 750 | 0.55 | $690.00-$1,000.00 | ||

| DH-1000 | 920 | 0.75 | $970.00-$1,40000 | ||

| DH-1200 | 1120 | 1.1 | $1,300.00-$1,900.00 | ||

| DH-1500 | 1420 | 1.5 | $1,800.00-$2,600.00 | ||

| DH-1800 | 1720 | 2.2 | $2,300.00-$3,700.00 |

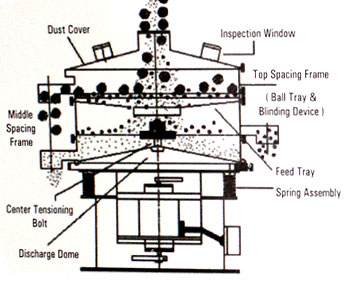

Vibro Sifter Machine consists of feeding port, dust cover, discharge port, beam ring, screen, net cleaning device, bouncing ball, counterweight, upper weight, vibrating body, vibration motor, spring, lower weight, base etc. composition.

Dahan vibro sifter machine manufacturer sells vibro sifter, ultrasonic vibro sifter, round vibro sifter, stainless steel vibro sifter, large vibro sifter, medicine vibro sifter, food vibro sifter and other equipment, models are 400mm-2000mm optional, materials are stainless steel, carbon Steel and plastic are optional; special customizations include gate type, explosion-proof type, mobile type, edged type, screen frame heightened type, etc., users can choose according to their needs.