Focus Sifter Machine Production

Powder Sieving Machine is a special equipment for powder screening and impurity removal; it can be sieved to 500 meshes, and the powder can be screened into 2-5 different specifications.

Price: $500.00-$3000.00/Set

Screening mesh: 500 mesh (25 microns) Output: 1-5 t/h

Diameter: 400mm-2000mm Level: 1-5 layers

Material: Carbon steel, stainless steel, plastic

Customized: standard type, ultrasonic type, gate type, explosion-proof type, mobile type

Materials: flour, ceramic powder, coal powder, medicinal powder, additives, alloy powder, graphite powder, glass powder and other powder screening in various industries

Powder Sieving Machine can be used for sieving and removing impurities of powdery materials such as flour, ceramic powder, coal powder, metal powder and food additives within 500 meshes. It can break up powder agglomeration and remove impurities in powder. The powder sieving machine has a built-in bouncing ball device to prevent the screen from clogging and speed up material screening. The screening efficiency can reach 99%, and the output can reach 5 tons; there are two types of carbon steel and stainless steel; the screen has 1-5 layers to choose from, The powder can be sieved into 2-5 different grades.

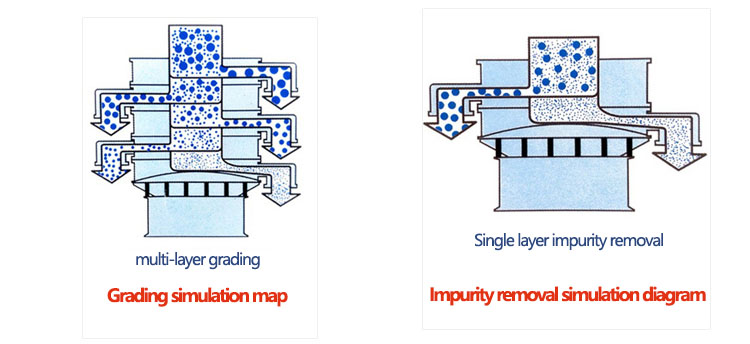

Classification: The powder can be sieved into 2-5 different grades, and the classification accuracy can reach 95%. Multi-layer Powder Sieving Machine is selected;

Impurity removal: Remove the agglomerates, unqualified materials or impurities in the powder, and the impurity removal accuracy can reach 98%. A single-layer Powder Sieving Machine is used.

powder sieving machine for flour

Screening mesh: 100 mesh

Screening output: 1.5-2 tons/hour

Recommended model: Type 1000 (single layer, stainless steel)

powder sieving machine for ceramic powder

Sieve mesh: 100 microns, 0.8mm, 0.4mm, 0.1mm

Screening output: 200 kg/hour

Model: 800 type (three layers)

powder sieving machine for pulverized coal

Screening mesh: 150 mesh - 200 mesh

Screening output: 3 tons/hour

Recommended model: Type 1200

Powder sieving machine can be used for flour, starch, milk powder, chili powder, turmeric powder, coffee powder, medicinal powder, coal powder, ceramic powder, alloy powder, graphite powder, battery material, 3D printing powder, powder coating, food powder within 500 mesh , Metal powder, bread flour, stone powder, heavy calcium powder, chemical powder and other powder materials screening, is used in food, chemical, pharmaceutical, metallurgy, ceramics, abrasives and other industries.

| materials | material diagram | proportion | Screen mesh number | method | Screening yield | model |

| flour |  |

0.6 | 24 mesh | Dry | 1500kg | DH-1000-1S |

| wheat starch |  |

1 | 250 mesh | wet | 3200kg | DH-1200-1S |

| corn starch |  |

0.6 | 40 mesh | Dry | 1600kg | DH-1000-1S |

| Chinese medicine powder |  |

0.8 | 80 mesh | Dry | 550kg | DH-800-1S |

| PVC resin powder |  |

1 | 10mm/5mm | Dry | 3000kg | DH-1200-2S |

| Polyethylene powder |  |

0.45 | 48/100 mesh | Dry | 100kg | DH-800-2S |

| graphite powder |  |

1.2 | 16/40/80 mesh | Dry | 1400kg | DH-1000-3S |

| lead powder |  |

11.34 | 10/80 mesh | Dry | 1000kg | DH-1000-2S |

| activated carbon |  |

4 | 60 mesh | Dry | 3000kg | DH-1000-1S |

| aluminum powder |  |

0.9/1.2 | 80/120 mesh | Dry | 350kg | DH-800-2S |

| electrode powder |  |

0.95 | 20/200 mesh | Dry | 550kg | DH-1000-2S |

| Kaolin |  |

0.4 | 100 mesh | Dry | 200kg | DH-1000-1S |

What is the Powder Sieving Machine material?

Powder Sieving Machine is available in carbon steel, stainless steel and plastic.

| material | carbon steel | Stainless steel | plastic |

| application | General material screening | It is used for powder screening with hygiene requirements; such as: flour in food, medicine, chemical industry, traditional Chinese medicine powder, etc. | It is used for screening powder materials that are easily oxidized by metal contact, such as: nylon powder, plastic powder, aluminum trichloride powder, etc. |

How many layers does the Powder Sieving Machine have?

The Powder sieving machine has 1-5 layers of sieve frames to choose from, which can sieve a powder into 2-6 different thicknesses.

| Hierarchy | impurity removal | Grading | |||

| single layer | double layer | Three layers | four layers | five layers | |

| One layer of screen mesh, two discharge ports | Two-layer screen, 3 discharge ports | Three-layer screen, 4 discharge ports | Four-layer screen, 5 discharge ports | Five-layer screen, 6 discharge ports | |

Different Types of Powder Sieving Machine

Powder sieving machine can be customized according to the different materials to be processed, including ultrasonic type, explosion-proof type, gate type, mobile type, heightened screen frame type, heightened bottom bucket type, etc.

| product category | normal type | Ultrasonic | gate type | Explosion-proof |

| Features | Regular model | Install ultrasonic screening system to prevent mesh clogging | A gate is installed at the discharge port to extend the screening time | Adopt explosion-proof vibration motor |

| application | Screening of ordinary powdery materials | Screening of fine powder materials with strong adsorption, high static electricity, easy agglomeration and light specific gravity | Screening of ultra-light and ultra-fine powder materials | Inflammable and explosive powder screening occasions |

Fine screening: The powdery materials can be screened to 500 mesh or 0.028mm.

Non-blocking net: It is equipped with a bouncing ball cleaning device, which can achieve the purpose of cleaning the net by continuously hitting the screen, which can prevent the mesh from being blocked. For viscous and electrostatic materials, an ultrasonic cleaning device can be installed.

Automatic discharge: The discharge port can be rotated 360°, impurities and coarse materials are automatically discharged, and continuous operation is possible.

No pollution: fully enclosed structure, no dust spillage, low noise and low energy consumption.

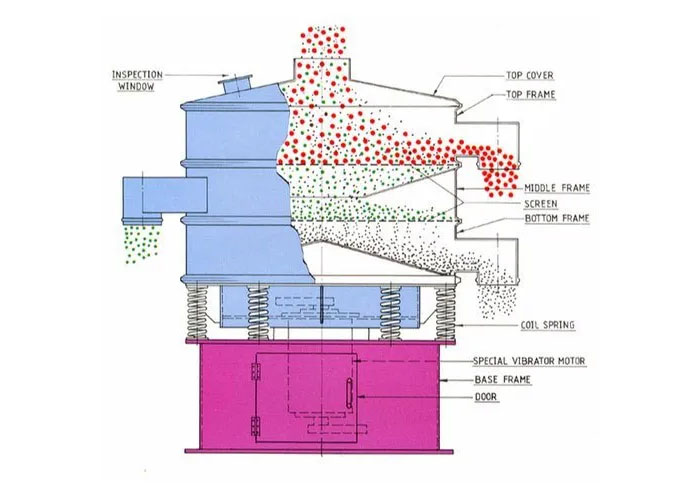

When the powder sieving machine is working, the vibration motor is used as the excitation source, and the powder material is poured into the powder sieving machine from the feeding port. Under the action of the vibration motor, the powder material spreads from the middle to the surrounding on the sieve surface, doing horizontal, vertical The inclined three-dimensional movement, the material larger than the aperture of the current layer is directly discharged from the discharge port; the material smaller than the aperture of the screen falls into the lower screen and continues to be screened until it is discharged from the discharge port.

| Model | Diameter mm | Screen area m2 | Screen specification (mesh) | Feeding granularity mm | Vibration time rpm |

| DH-600 | Φ600 | 0.24 | 2-500 | <Φ10 | 1500 |

| DH-800 | Φ800 | 0.45 | 2-500 | <Φ15 | 1500 |

| DH-1000 | Φ1000 | 0.67 | 2-500 | <Φ20 | 1500 |

| DH-1200 | Φ1200 | 1.0 | 2-500 | <Φ30 | 1500 |

| DH-1500 | Φ1500 | 1.6 | 2-500 | <Φ30 | 1500 |

| DH-1800 | Φ1800 | 2.43 | 2-500 | <Φ30 | 1500 |

| DH-2000 | Φ2000 | 3.01 | 2-500 | <Φ30 | 1500 |

Powder sieving machine is composed of inlet, dust cover, outlet, bundle ring, screen, counterweight, upper hammer, vibrating body, vibrating motor, spring, lower weight, base and other parts.

Dust cap: prevents the material from spreading outward, and can also protect the external dust from entering, thereby contaminating the screening material.

Bundle ring: used to fix the sieve frame part in the middle of the sieve body.

Upper heavy hammer, lower heavy hammer: changing the phase angle of the upper and lower heavy hammer of the vibration motor motor can change the movement trajectory and residence time of the material on the screen.

Spring: vibration damping and sound insulation.

Machine base: support the entire vibrating screen and keep its work stable.

Dahan Powder sieving machine manufacturer integrates production, design and sales, mainly provides powder sieve, standard Powder sieving machine, stainless steel Powder sieving machine, all stainless steel Powder sieving machine, ultrasonic Powder sieving machine, mobile Powder sieving machine, sieve frame Heightened Powder sieving machine, gate Powder sieving machine, bottom barrel heightened Powder sieving machine and other equipment, with diameters of 400mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm, 2000mm, etc., and materials such as carbon steel, stainless steel 304/316L, plastic, etc. , there are 1-6 layers to choose from, you can choose according to your needs.