Focus Sifter Machine Production

Particle Size Sieve is a common instrument for particle size detection and analysis of powders and granular materials.

Price: $200.00-$3,680.00/Set

Sieve mesh: 0.025-3mm

Layer(s): 1 - 7

Sieve diameter: 75,100, 200, 300,400

Particle Size Sieve is an instrument for particle size detection and analysis of various materials, which can be used for particle size composition inspection of ordinary abrasives and production grading and particle size inspection of superhard materials, as well as the particle size structure, liquid and solid substance content and abrasive screening, filtration and detection of granular and powdery materials; Simple operation, automatic timing, accurate detection.

Testing pharmaceutical powders:very fine powder No. 8 sieve (150 mesh) No. 9 sieve (200 mesh) no less than 95% of the powder.

The milk powder is sieved into different grades: ultrasonic laboratory sieve shaker is used, with automatic net cleaning function, which can avoid mesh clogging.

Detection of metal powder: sieve the metal powder into 4 grades such as 140 mesh, 200 mesh, 230 mesh, and 325 mesh.

Particle Size Sieve can be used in various laboratories, laboratories and other inspection departments for particle size analysis and screening of granules and powdered materials, specific materials are flour, aggregates, pulverized coal, soil, powder, quartz sand, etc.

1. Choose high-quality stainless steel materials such as SUS316 corrosion resistance, SUS304 stainless steel, 08F steel plate (chromium-plated), aluminum plate and other materials stretched and formed at one time, no rust, non-magnetic, precise fit, no material leakage and water leakage, wall thickness 0.6mm, durable and not deformed, surface polishing, exquisite and beautiful.

2. The screen and the screen frame are welded and connected, which can withstand 400 ° high temperature and can be used for inorganic and organic solutions. The connection is firm, gap-free, and does not clamp materials.

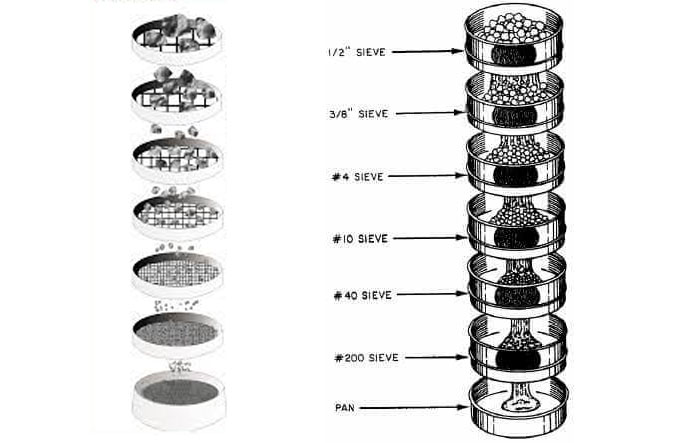

3. It can be installed and used in multiple layers, and can divide a material into 2-7 different particle segments at the same time.

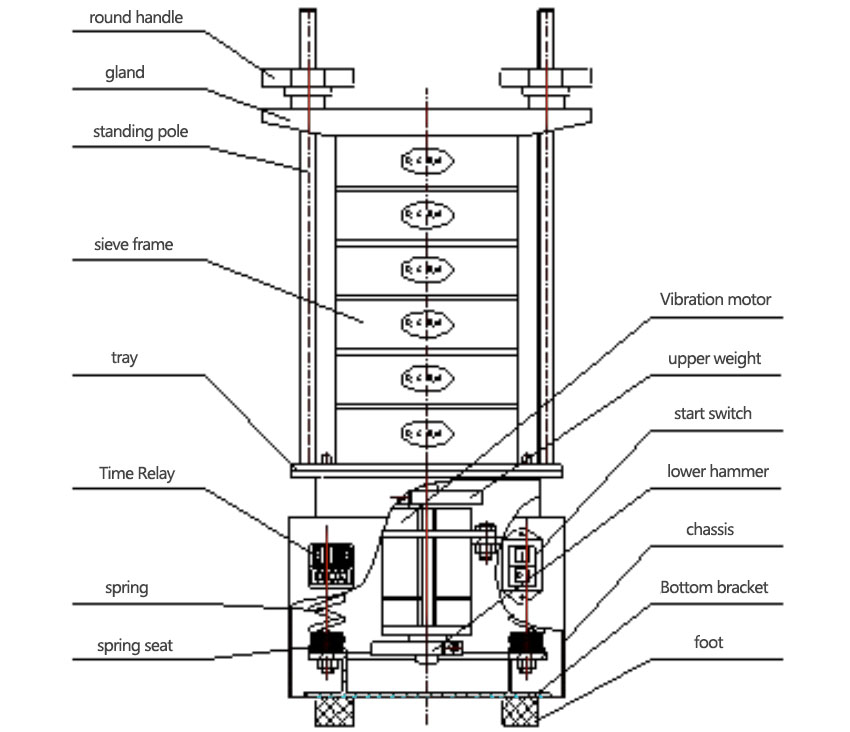

4. The inspection and screening time is controlled by the time relay, and the time and accuracy of the empty time inspection time are accurate.

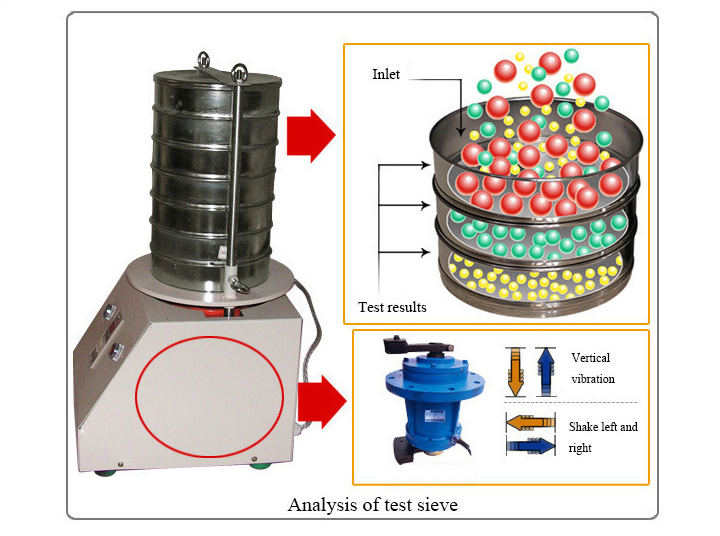

5. It can be combined with ultrasonic screening system to automatically clean the screen to improve screening efficiency and detection accuracy.

Particle Size Sieve screen frames are available in stainless steel, brass and nylon, woven mesh, perforated plates and electroforming.

Particle Size Sieve adopts a vertical vibration motor as the vibration source of the whole machine, and transmits the vibration to the screen frame through the vibration plate; The material particles smaller than the pore size of the screen are screened to the lower screen frame, so that each test screen only leaves the same particle size of the material, to achieve the separation of different particle sizes, to determine the particle size composition of the material, so that the screen frame material can be very effectively used for filtration, classification and screening purposes.

| NO. | Name | Unit | Parameter |

| 1 | frame diameter | mm | φ200 |

| 2 | the number of layer | s | 1~8 |

| 3 | sieve size | mm | 0.025-3 |

| 4 | vibrating amplitube | mm | 1~4 |

| 5 | vibration frequency | n/min | 1440 |

| 6 | power supply | V;HZ;KW | 220;50;0.12 |

| 7 | outside dimension | LWH | 350*350*(300+n*56) |

| 8 | machine weight | kg | 36 |

| 9 | time alarm | s | 999 |

| 10 | noise | db | Less than 50 |

Particle Size Sieve is composed of fixed brass nut, pressure plate, screen cover, screen frame, middle screen frame, screen bottom, isometric adjustment rod and other components.