Focus Sifter Machine Production

Two screening methods of swing and slap vibration are adopted, and the material is unloaded quickly and the material is not blocked.

Sieve diameter: 75mm, 200mm, 300mm

Slap height: 38mm

Slap times: 156±3 times/min

Number of rotations: 290±6 times/min

Available time: 0-99 minutes

The number of sieve layers: 1-7 layers

Rotap Sieve Shaker is a commonly used particle size testing instrument in the laboratory. It can be equipped with special fixtures, which can clamp 75mm, 100mm, 200mm test sieves. The clamping is convenient and flexible, the clamping is firm, and it can automatically stop; it is suitable for ordinary abrasive particle size composition inspection. , Superhard material production grading and material inspection.

Rotap Sieve Shaker can be used for diamond micropowder, abrasive particle size composition inspection and superhard material production grading and material composition inspection. The material is screened and tested, the specific materials are: diamond, abrasive, silicon powder, peat granules, activated carbon, copper powder, medicinal powder, soil.

Rotap Sieve Shaker for Metal Powder Inspection

Rotap sieve shaker for testing abrasives

Single-seat Rotap Sieve Shake: Can only install group sieve frames and can only handle 1 type of material.

Two-seat Rotap Sieve Shake: 2 sets of sieve frames can be installed to achieve the effect of screening 2 different materials at the same time.

When the Rotap Sieve Shaker is working, the main shaft rotates after the gear speed is synchronously driven by the vibration motor. The main shaft drives the eccentric wheel to make the slide plate shake the test sieve left and right, and at the same time drives the ejector pin gear to rotate. Sieve.

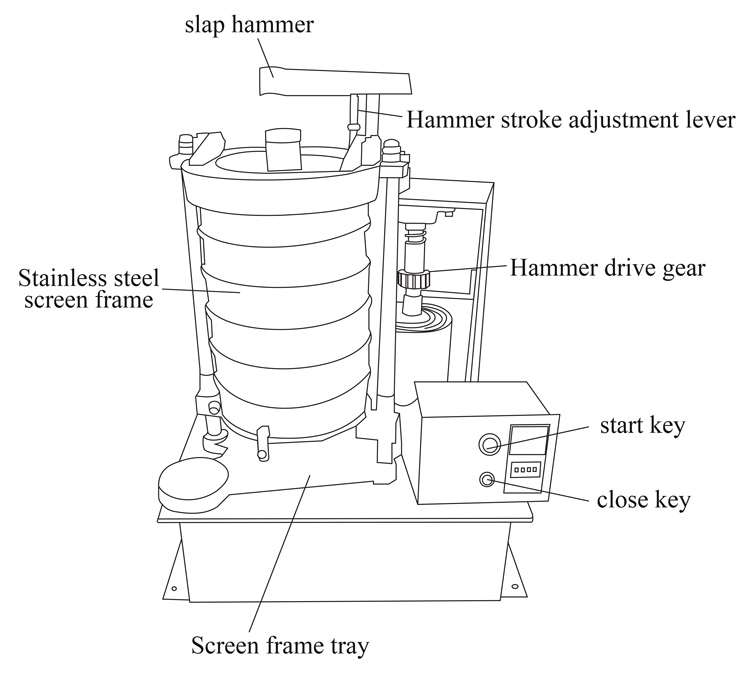

Rotap sieve shaker consists of machine base, sieve frame, tray, transmission mechanism, beat hammer and so on.

Small size, light weight, low noise, easy to use and flexible clamping

The structure is compact and novel, which can effectively guarantee the shaking and jacking times of the sieve

Good screening effect, uniform screening strength and frequency

The whole machine has good performance, large rotating amplitude and strong vibration force

Screening time can be controlled regularly and the data of screening is accurate

| NO | Name | Unit | Parameter |

| 1 | Sieve diameter | mm | Φ200 |

| 2 | The quantity of layer | s | 1-7 |

| 3 | Number of revolution | Timed/min | 290±6 |

| 4 | tapping | Timed/min | 1-4 |

| 5 | Tapping height | KN | 38±6 |

| 6 | Levelness of the base | mm/min | ≤0.6 |

| 7 | Motor powder | KW | 0.37 |

| 8 | Powder supply | V | 380,220 |

| 9 | Outside dimension | LWH | 433*432*785 |

| 10 | Rotation distance | mm | 25 |