Focus Sifter Machine Production

Linear vibrating screen is a horizontal type screen machine for particle materials and other,it is also called liner motion vibrating screen.

Feeding granularity: 0.074-10mm

Handling capacity: 0.12-20t/h

Weight:5500-60000

Various optional specifications with customization

Key Points: Equipped sprinkle for clean,safe development, large output

Linear Vibrating Screen is suitable for all kinds of dry powder or granular materials with material particle size of 0.074-5mm, moisture content less than 70% and no stickiness. Linear Vibrating Screen is driven by dual motors, which can automatically discharge materials, with large output and energy consumption Low, more suitable for 24-hour assembly line operations.

DZSF type linear vibrating screen is also called linear vibrating screen.

linear vibrating screen for glitter powder

linear vibrating screen for sorting walnut kernels

linear vibrating screen for wheat bran

Linear vibrating screen particle size is 0.074-5mm, sieving moisture content <7%, non-viscous dry powder or granular materials, such as: starch, sesame, peanut, soybean, activated carbon, fertilizer, coke, plastic particles, melon seeds, Iron slag, wheat bran, corn, spices, salt, starch, traditional Chinese medicine powder, granular pills, pellets, refractory materials, kaolin, lime, alumina, quartz sand, lead powder, aluminum powder, etc. The output is up to 20 tons/hour.

1. It can screen granular materials below 400 mesh, and the screening efficiency can reach more than 96%.

2. The 1-6 layers of screen mesh design can screen 2-7 kinds of materials with different particle sizes at the same time to meet the needs of different customers.

3. Driven by double motors, the excitation force is large, the output can reach 20 tons/hour, and the energy consumption can be reduced by 30%.

4. The linear vibrating screen adopts a fully enclosed structure without dust spillage.

5. The replacement of the screen is simple and quick, only 3 to 5 minutes, and the screen material has a variety of choices (nylon, PP mesh).

Linear vibrating screen is powered by a two-vibrator motor, and when two vibrators are synchronized and anti-rotating, the excitability of the vibrating motor is offset in parallel to the axis of the oscillating motor, and it's overlapping in the direction of the axis of the vibrating motor, and so the movement of the shaker is in a straight line. The two motor shafts have an inclination relative to the screen surface. Under the combined force of excitation force and material gravity, the material is thrown up on the screen surface and moves forward in a straight line. Through different levels of screen mesh, the above and below materials of various specifications are screened.

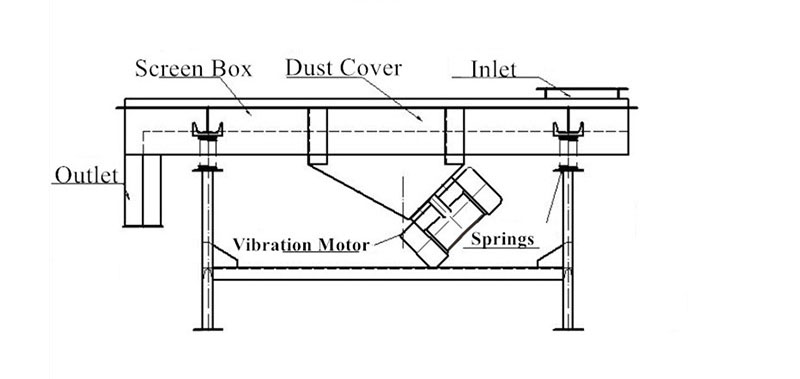

Linear Vibrating Screen consists of screen box, screen frame, screen mesh, vibration motor, motor pedestal, vibration damping spring, bracket and so on.

1. Screen box: It is welded by several kinds of steel plates with different thicknesses. It has certain strength and rigidity and is the main component of the screen machine.

2. Screen frame: made of pine or wood with less deformation, it is mainly used to keep the screen flat and achieve normal screening.

3. Screen: There are several kinds of screens such as low carbon steel, brass, bronze, stainless steel wire.

4. Vibration motor (for use and maintenance methods, please refer to the vibration motor instruction manual).

5. Motor pedestal: When installing the vibration motor, the connecting screws must be tightened before use, especially three days before the trial of the new screen machine, it must be tightened repeatedly to avoid accidents caused by loosening.

6. Vibration damping spring: prevent the vibration from being transmitted to the ground and support the full weight of the screen box. When installing, the spring must be vertical to the ground.

7. Bracket: It consists of four pillars and two channel steels, which support the screen box. When installing, the pillars must be perpendicular to the ground, and the channel steels below the two pillars should be parallel to each other.

Determine the purpose of use

The linear vibrating screen mainly removes and classifies powder and granular materials; impurity removal: choose single-layer screen, classification: choose multi-layer screen (there are 2-6 layers of screen, which can be selected according to needs).

Determine the material name and attributes

Know whether the material is powder or granule, the specific gravity of the material, whether it is sticky or not, and whether it is wet. The characteristics of the material directly affect the screening effect.

Yield requirements

The output of the linear vibrating screen can reach 20 tons/hour. Different users have different requirements for the output of materials, and the models selected for different output are different.

Plus: DZSF515 to DZSF1030,which has more than 5 models for your choice, also supports customization services!

| Model |

Screen size (mm) |

Mesh size mesh |

Handling capacity (t/h) |

Vibration time |

| DZSF515 | 500×1500 | 2-200 | 0.12-20 | 960 |

| DZSF520 | 500×2000 | 2-200 | 0.12-20 | 960 |

| DZSF525 | 500×2500 | 2-200 | 0.12-20 | 960 |

| DZSF1020 | 100×2000 | 2-200 | 0.11-20 | 960 |

| DZSF1025 | 1000×2500 | 2-200 | 0.18-15 | 960 |

| DZSF1030 | 1000×2500 | 2-200 | 0.1-20 | 960 |