Focus Sifter Machine Production

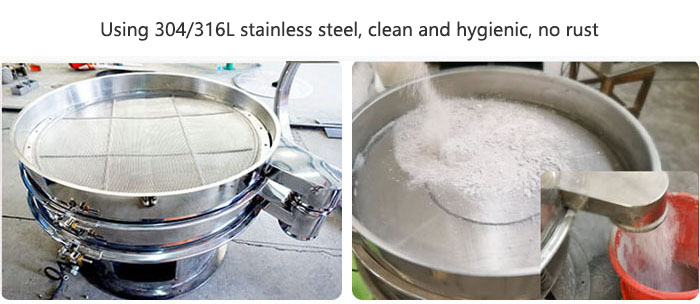

Flour Sieve Machine is made of 304/316 stainless steel, clean and hygienic. It can sieve flour within 500 meshes, remove lumps and irregular foreign objects in flour, and quickly break up flour agglomerates.

Price: $700.00-$4,600.00/Set

Feed particle size: 2-500 mesh (or 0.028mm)

Screening output: 1-5 tons/hour

Material: 304 stainless steel and 316L stainless steel

Number of layers: 1 - 5 layers (two layers are commonly used)

Customized: ultrasonic, gate type, explosion-proof type

Flour mesh: 12 mesh, 20 mesh, 24 mesh, 30 mesh, 40 mesh, 60 mesh

Materials: flour, breadcrumbs, starch, wheat flour, corn flour, milk powder, etc

Flour Sieve Machine is mainly used to remove impurities such as silk threads, stones, bran, insect eggs and agglomerates contained in flour. The sifted flour can also be loosened when making fluffy fine pastries to make sure the flour is fluffy enough without clumping. The Flour Sieve Machine is made of stainless steel, which is clean and hygienic, and meets the hygiene requirements of the food industry, which can prevent flour from being polluted during sieving.

Flour sieve machine can be used for flour screening and impurities.

Flour grading: Multi-layer Flour Sieve Machine is used, with 1-5 layers of sieves optional, which can sieve flour into 2-6 different finenesses, and the grading accuracy reaches 95%.

Flour impurities: A single-layer Flour Sieve Machine is used, which can accurately separate flour and impurities in flour, with a removal rate of 98%.

Flour Sieve Machine is mainly used for screening and removing impurities within 600 mesh of semolina, starch, bread flour, soybean flour, milk powder, wheat flour, corn flour and other powdery materials.

| materials | Way of working | Screen (mesh/inch) | Handling capacity (kg/hour) | model |

| milk powder | dry | 16-20 | 2000 | DH-1200-1S |

| starch | dry | 80 | 1200 | DH-2000-2S |

| wheat starch | Wet | 200 | 3200 | DH-2000-1S |

| flour | dry | 24 | 1500 | DH-1000-1S |

Household flour: 40 mesh-60 mesh

Pure flour to remove impurities, use 14-24 mesh

CB30 means silkworm (C) silk material, half (B) twisted form (single twist), 30 meshes per square centimeter

CB30-76 mesh CB36 sieve-91 mesh, CB42 sieve-107 mesh

All bread flour passed through the CB30 sieve, and no more than 15.0% of the remaining in the CB36 sieve;

All the noodles used in the noodles are passed through the CB36 sieve, and no more than 10.0% of the CB42 sieve is retained;

All steamed bread flour passed through CB36 sieve;

All dumpling flour is passed through the CB36 sieve, and no more than 10.0% of the CB42 sieve is retained;

All the flour for the crispy biscuits is passed through the CB36 sieve, and no more than 10.0% of the CB42 sieve is retained.

Flour is the main raw material of bread, cakes and steamed buns. Due to storage time and environmental problems, flour may agglomerate. Therefore, Flour Sieve Machine is required for screening. Generally, a 40-mesh sieve is used to screen flour.

| flour state | mesh | Handling capacity (kg/hour) |

| dry | 20 mesh(0.8mm) | 2000 |

| 30 mesh(0.55mm)/45 mesh(0.18mm) | 1500 | |

| 80 mesh(0.18mm) | 1200 |

The commonly used sieve meshes of Flour Sieve Machine are 12 mesh, 20 mesh, 24 mesh, 30 mesh, 40 mesh and 60 mesh; the mesh number can be selected according to the desired flour fineness.

The flour can be sieved to 500 mesh or 0.028mm to improve the fineness and precision of the flour.

The whole machine is made of 304/316L stainless steel and polished inside and out, which is clean and hygienic, not easy to rust, and not easy to pollute the flour.

Built-in special silicone ball cleaning device for food industry, the screen is not easy to be blocked, and the screening efficiency is improved.

The fully sealed structure can prevent the pollution of the environment caused by flour spillage.

After the Flour sieve machine is started, its power device is the eccentric blocks with different phases at the upper and lower ends of the vibration motor. Due to the high-speed placement, a compound inertial force is generated. Under the action of continuous reciprocating motion, it drives the screen surface to vibrate periodically, so that the flour on the screen surface moves with the screen box. The flour smaller than the sieve hole diameter falls to the lower layer through the sieve hole and becomes the under-sieve, and the flour larger than the sieve hole diameter is discharged from the discharge port, thereby separating the flour through the sieve.

Plus: DH500-DH200,which has more than 5 models for your choice, also supports customization services!

| Model | Diameter mm | Screen area m2 | Screen specification(mesh) | Feeding granularity mm | Vibration time rpm |

| DH-600 | 600 | 0.24 | 2-500 | <10 | 1500 |

| DH-800 | 800 | 0.45 | 2-500 | <15 | 1500 |

| DH-1000 | 1000 | 0.67 | 2-500 | <20 | 1500 |

| DH-1200 | 1200 | 1.0 | 2-500 | <30 | 1500 |

| DH-1500 | 1500 | 1.6 | 2-500 | <30 | 1500 |

| DH-1800 | 1800 | 2.43 | 2-500 | <30 | 1500 |

| DH-2000 | 2000 | 3.01 | 2-500 | <30 | 1500 |

Dahan Flour Sieve Machine manufacturer produces flour sieve, stainless steel Flour Sieve Machine, ultrasonic Flour Sieve Machine, mobile Flour Sieve Machine, gate type Flour Sieve Machine, explosion-proof Flour Sieve Machine, large Flour Sieve Machine, small Flour Sieve Machine and other equipment, diameter 400mm-2000mm, output 1-5 tons, price as low as $500.