Focus Sifter Machine Production

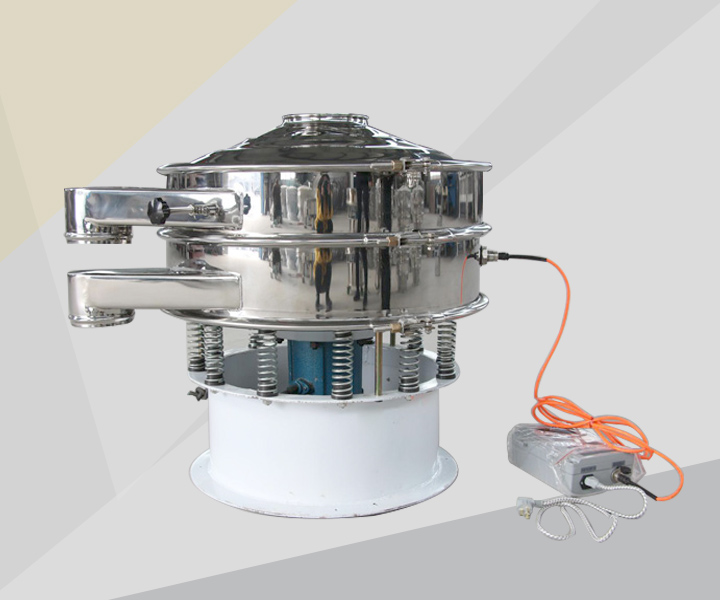

Powder Sieve is the ideal equipment for powder screening and impurity removal in various industries within 600 mesh.

Price: $500.00-$3,500.00/Set

Feeding granularity: 80-600 meshes

Processing capacity: 1-5 T

Model: 400mm-2000mm

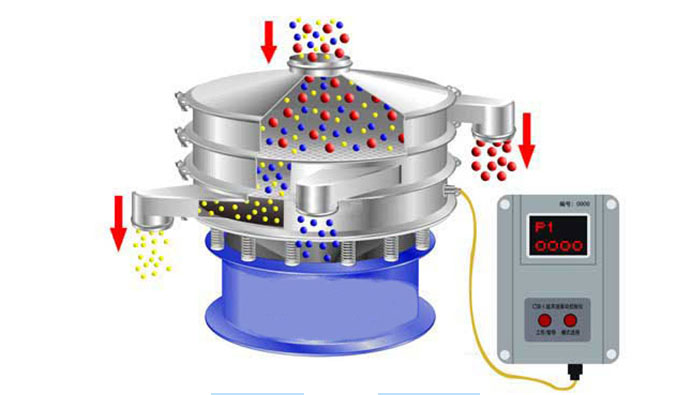

Layer(s) : 1-5

Material: carbon steel, stainless steel + carbon steel, all stainless steel, plastic

Powder Sieve is an ideal screening equipment for powder screening and screening of agglomerates and impurities. It can screen all powder materials within 600 meshes. For different powders, ultrasonic Powder Sieve (special for fine powder), explosion-proof Powder Sieve ( Flammable and explosive powders are commonly used). Dahan Powder Sieve for sale has a wide range of models and specifications, with prices starting as low as $450.

| Feature | Screening and cleaning of powders | Application | Screens viscous, static, agglomerated powders from 36 microns to 25 mm |

| Material | Carbon Steel, Stainless Steel 304 and 316 | Key words | Powder Sieve for sale |

| Custom made | Bespoke acceptance by your screening material | Advantage | High precision sieving to submit powder quality |

| Cleaning system | Ultrasonic screening system | Layers | 1-5 layers |

| Mesh size | 80-600 mesh | Voltage | 380V/custom |

The price of Powder sieve is related to the material, model, level, customization, manufacturer, etc., the price is different for different choices

Powder Sieve Model Price

| Model | Price($) | ||

| 1 Layer | 2 Layer | 3 Layer | |

| DHC-600 | 860 | 970 | 1200 |

| DHC-800 | 890 | 1100 | 1500 |

| DHC-1000 | 1260 | 1520 | 1700 |

| DHC-1200 | 1690 | 2300 | 2600 |

Powder Sieve Material Price

Powder sieve is made of stainless steel (specially used in food/medicine industries with hygienic requirements), carbon steel (common material screening, low cost); the price comparison of different materials of the same model and level is as follows:

| Model | layers | stainless steel ($) | carbon steel ($) |

| DHC-400 | 1-5 | 550-1030 | 440-960 |

| DHC-600 | 1-5 | 740-9000 | 550-1030 |

| DHC-800 | 1-5 | 1110-1770 | 810-1180 |

| DHC-1000 | 1-5 | 1400-2300 | 1030-1500 |

| DHC-1200 | 1-5 | 1770-4130 | 1300-2400 |

| DHC-1500 | 1-5 | 2520-4000 | 1920-3100 |

| DHC-1800 | 1-5 | 3400-5800 | 2100-3300 |

| DHC-2000 | 1 | 5600 | 3000 |

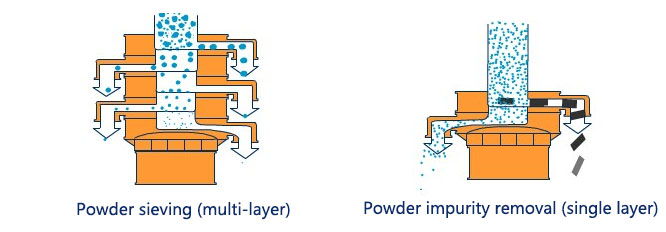

Powder sieving (multi-layer): The powder can be sieved into 2-6 different fineness.

Powder impurity removal (single layer): remove agglomerated and unqualified materials in the powder.

Screening Ceramic powder

Sieving Metal powder

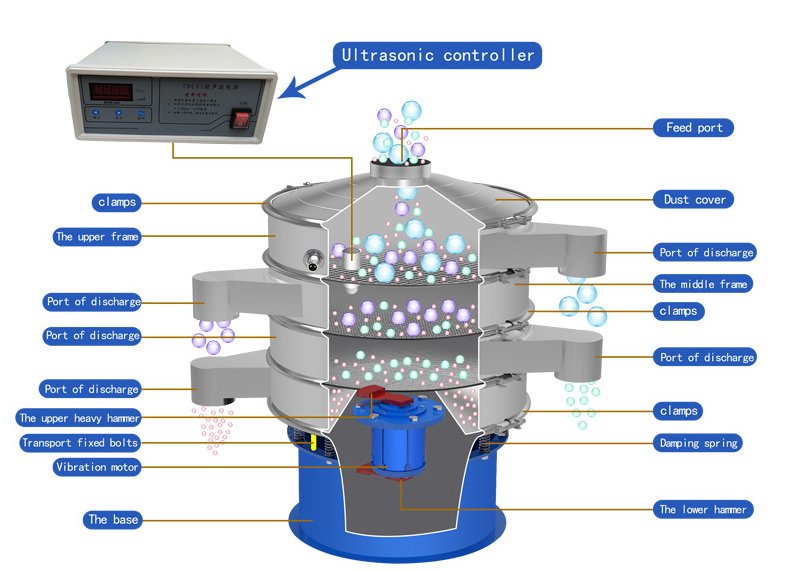

When the Powder sieve is working, it can input 220V, 50Hz or 110V, 60Hz electric energy into the ultrasonic transducer to convert it into 36KHz mechanical vibration, and the generated ultrasonic wave makes the screen vibrate at high frequency, and the vibration frequency can reach 36000 per second Second, it can make the fine powder material form a micro-suspension state on the sieve, pass through the sieve faster, without generating static electricity and sticking to the sieve, and achieve the effect of sieving and cleaning at the same time.

| model | Sieve Diameter (mm) | Power (kw) | Grain size (mm) | Voltage (V) | Price ($/unit) |

| DH-400 | 350 | 0.18 | <10 | 380 | $400.00-$550.00 |

| DH-600 | 550 | 0.25 | $584.00-$830.00 | ||

| DH-800 | 750 | 0.55 | $690.00-$1,000.00 | ||

| DH-1000 | 920 | 0.75 | $970.00-$1,40000 | ||

| DH-1200 | 1120 | 1.1 | $1,300.00-$1,900.00 | ||

| DH-1500 | 1420 | 1.5 | $1,800.00-$2,600.00 | ||

| DH-1800 | 1720 | 2.2 | $2,300.00-$3,700.00 |

1. While achieving high-precision and high-mesh sieving, it can control a narrow particle size range.

2. The screening accuracy can be increased by 1-70%, and the output can be increased by 0.5-10 times.

3. The self-cleaning function of the screen: more than 500 mesh screening, no mesh blockage, no screening efficiency attenuation.

4. Solve the screening problems such as strong adsorption, easy agglomeration, high static electricity, high precision, high density and light specific gravity.

Powder Sieve is mainly composed of ultrasonic resonance power supply, oscillator, outer mesh ring and resonance ring, screen mesh, mesh frame, vibration motor, damping spring and other parts.

The powder sieve is superimposed with ultrasonic vibrations to prevent clogging of the mesh, resulting in improved yield and quality. It has been successfully used in the screening and classification of 400 mesh, 500 mesh and 600 mesh ultrafine materials, such as powder coatings, silicon carbide, alloy powder, molybdenum powder, stainless steel powder, tungsten powder, nickel powder, cobalt powder, powder coating, quartz Powder, fluorspar powder, bumidone powder, malt powder, ribavirin, coffee powder, electromagnetic powder, negative electrode material, laser powder, electromagnetic powder, magnesium oxide, lithium battery positive electrode material, negative electrode material, carbon powder, spore powder and other materials.

| raw material | proportion | mesh | model | method | Screening output (kg/hour) |

| wheat starch | 1 | 250 mesh | DHC-1200-1S | Wet | 3200 |

| flour | 0.6 | 24 mesh | DHC-1000-1S | Dry | 1500 |

| Chinese medicine powder | 0.8 | 80 mesh | DHC-800-1S | Dry | 550 |

| PVC resin powder | 1 | 0㎜/5㎜ | DHC-1200-2S | Dry | 5000 |

| graphite powder | 1.2 | 16/40/80 mesh | DHC-1000-3S | Dry | 3000 |

| aluminum powder | 0.9/1.2 | 80/120 mesh | DHC-800-2S | Dry | 1400 |

Dahan Powder sieve manufacturers sell Powder sieve, stainless steel powder sieve, carbon steel Powder sieve, large Powder sieve, small Powder sieve, ultrasonic Powder sieve, etc., models are 400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm, etc.; According to different powders, it can also be customized, such as: gate Powder sieve, explosion-proof Powder sieve, mobile Powder sieve, etc.; Factory direct with prices as low as $500.00.