Focus Sifter Machine Production

Sieving machine is a special equipment for material screening, filtration and impurity removal.

Sieving machine price: $500.00-$5,600.00/Set

Feed particle size: 80-600 mesh

Feed particle size: 80-600 mesh

Screening output: 1-5 tons

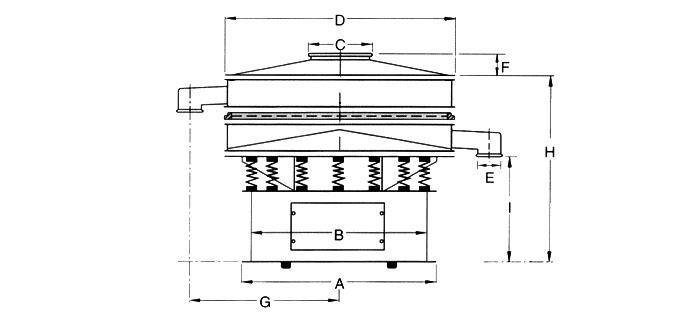

Model: 400mm - 2000mm

Material: carbon steel/stainless steel

Level: 1-5 layers

Customized: ultrasonic type, mobile type, edge type, gate type, feeding hopper

Sieving machine is mainly used for sieving powder, granule and liquid materials within 500 meshes. It can sieve, filter and remove impurities. The price is related to material, model, grade, customization, application material, etc.

Sieving Machine Price is related to the material, there are three kinds of materials: stainless steel, carbon steel and plastic

| material | Stainless steel | carbon steel | plastic |

| Price ($/unit) | $556.00-$5,280.00 | $400.00-$2,780.00 | $480.00-$4,500.00 |

| Features | 304/316L stainless steel, not easy to rust, special for food and pharmaceutical industries | Inexpensive, common materials are preferred | For materials that are easily oxidized in contact with metals, such as copper sulfate, plastic powder |

The price of Sieving Machine is related to the model, the models are 400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 2000mm.

| model | Sieve Diameter (mm) | Power (kw) | Grain size (mm) | Voltage (V) | Price ($/unit) |

| DH-400 | 350 | 0.18 | <10 | 380 | $400.00-$550.00 |

| DH-600 | 550 | 0.25 | $584.00-$830.00 | ||

| DH-800 | 750 | 0.55 | $690.00-$1,000.00 | ||

| DH-1000 | 920 | 0.75 | $970.00-$1,40000 | ||

| DH-1200 | 1120 | 1.1 | $1,300.00-$1,900.00 | ||

| DH-1500 | 1420 | 1.5 | $1,800.00-$2,600.00 | ||

| DH-1800 | 1720 | 2.2 | $2,300.00-$3,700.00 |

Sieving Machine Price is related to the level, Sieving Machine has single-layer, double-layer, three-layer, four-layer, and five-layer.

| Hierarchy | single layer | double layer | Three layers | Four layers | Five layers |

| Price ($/unit) | $400.00-$2,000.00 | $550.00-$2,300 | $1,200-$2,600.00 | $800-$3,000.00 | $1,200.00-$4,800.00 |

| Features | Dedicated for impurity removal/filtration, the material can be sieved into 2 specifications | Commonly used level, the material can be screened into 3 specifications | The material can be screened into 4 specifications | The material can be screened into 5 specifications | The material can be screened into 6 specifications |

Sieving Machine Price is related to customized products. Dahan sieving machine customized products include ultrasonic, mobile, explosion-proof, edged, gate, hopper, etc., and can also be designed according to your needs.

| custom made | ultrasonic | mobile | Explosion-proof | edge | gate type |

| price | $800.00-$3,000.00 | 5000-12000 | 4500-9000 | 3900-8600 | 4700-19000 |

| Features | Using ultrasonic system, suitable for sieving of superfine powder materials with adsorption, static electricity, easy to agglomerate, and easy to stick | The bottom is equipped with a universal wheel, which can move freely and is used for places that need to move back and forth | Use explosion-proof motor for flammable and explosive occasions | The design of the feeding port with edge can prevent the liquid from splashing and increase the feeding amount | The discharge port is equipped with a gate, which can control the material screening time |

Sieving machine is an equipment for grading, filtration and impurity removal of various powders, granules and liquid materials; the sieving is as fine as 500 mesh, and the filtration can reach 5 microns. Up to 5 tons, materials are carbon steel, stainless steel and plastic; there are 1-5 layers, models are 400mm-2000mm and so on.

Screening: 2-5 layers are optional, and the materials can be screened into 3-6 different specifications.

Impurity removal: The impurities and unqualified materials in the material can be screened cleanly, and the impurity removal rate can reach 98%.

Filtration: It can filter out the particulate matter/foreign matter in the liquid, and quickly realize solid-liquid separation.

sand sieving machine

quartz sand sieving machine

Powder Sieving Machine for epoxy

Sieving machine can be used for impurity removal, classification and filtration of powder, particle and slurry materials in food, medicine, chemical industry, abrasives, metallurgy and other industries. The specific materials are: flour, starch, milk powder, soybean milk, Chinese medicine powder, Chinese and Western medicine granules, rubber powder, resin powder, pigment, mud, quartz sand, etc.

Sieving machine can screen 500 mesh or 0.028mm, the screening efficiency is up to 95%, and the screening output is up to 5 tons.

It can be used for sieving, impurity removal and filtration of powder/granular/liquid materials.

There are 1-5 layers of sieves to choose from, single-layer impurity removal and filtration, and multi-layer screening, which can screen materials into 2-6 different specifications.

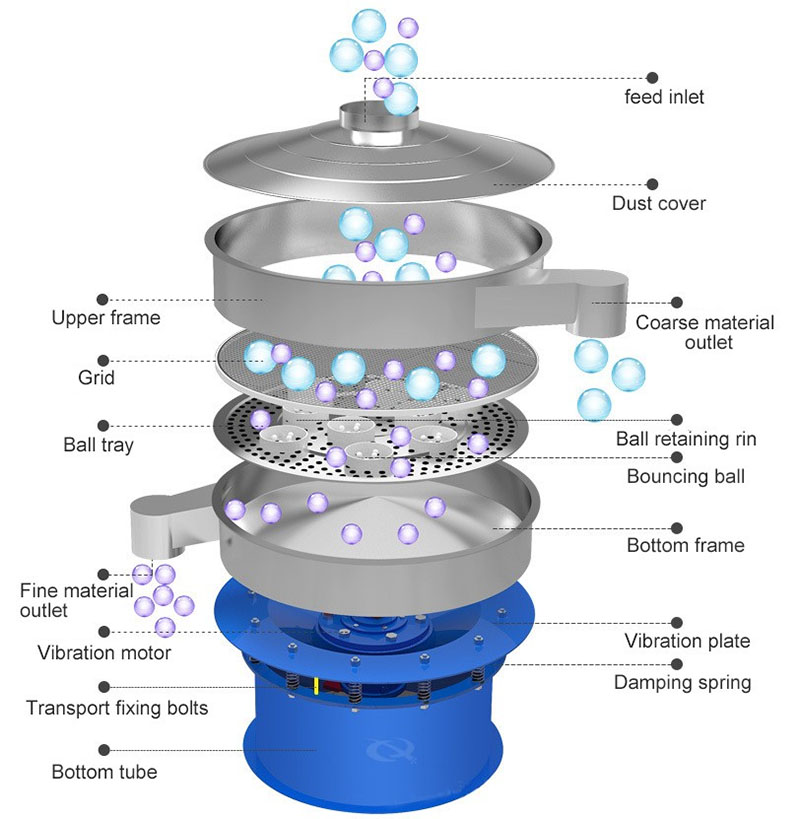

The built-in bouncing ball can automatically clear the net, prevent the mesh from clogging, and automatically discharge powder and impurities.

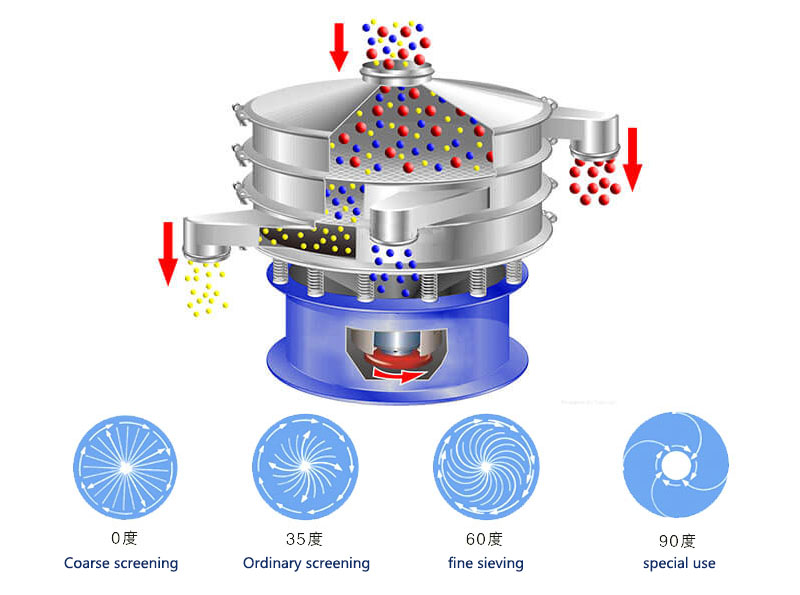

The Sieving machine is driven by a vibrating motor, so that the material enters the sieve machine and performs horizontal, vertical or inclined three-dimensional motion. We control the screening time and movement track of the material on the screen surface by adjusting the angle of the eccentric weights on both sides of the motor.

Sieving machine is composed of feeding port, dust cover, discharging port, beam ring, screen, counterweight, upper weight, vibrating body, vibration motor, spring, lower weight and machine base.

Dust cover: prevent the material from spreading outward, isolate the external dust from entering, and avoid contaminating the screening material.

Beam ring: Fix the screen frame in the middle of the screen body.

Upper weight and lower weight: change the phase angle of the upper and lower weights of the vibration motor to control the movement trajectory and screening time of the material.

Spring: Vibration and noise isolation.

Machine base: support the entire sieving machine and keep the work stable.