Focus Sifter Machine Production

Industrial Sifter is a special equipment for sieving powder and granular materials in food, chemical, pharmaceutical and other industrial industries.

Price: $800.00-$4,900.00/Set

Screening mesh: within 500 mesh (25 microns)

Output: 1-5 tons/hour

Industrial Sifter can screen powder, granular and liquid materials, remove impurities, filter, sieve to 500 mesh, and filter up to 5 microns; can add a cleaning device to reduce material clogging, materials are carbon steel, stainless steel, plastic Three types, 1-4 layers of screens can be added according to user requirements.

Grading (multi-layer): divide the powder/particles into 2-5 grades, with a grading accuracy of 95%;

Impurity removal (single layer): filter and remove the agglomerated or unqualified materials in the material, and the impurity removal accuracy can reach 98%.

Filtration (single layer): remove particulate matter/foreign matter in liquid material, filtration capacity up to 5t/h

Industrial Sifter can be used for impurity removal, classification and filtration of powder, granule and slurry materials in various industries.

Food industry: starch, milk powder, monosodium glutamate, soy milk, fruit juice, soy sauce, vinegar, etc.

Chemical industry: rubber powder, resin powder, pigment, washing powder, paint, soda ash, lemon powder, rubber, plastic, etc.

Pharmaceutical industry: Chinese medicine powder, pharmacy, Chinese and Western medicine granules, etc.

Metallurgical industry: titanium oxide, zinc oxide, electromagnetic materials, metal powder, electrode powder, etc.

Abrasives, ceramic industry: alumina, quartz sand, mud, spray soil particles.

1. Wide range of materials, it can be screened to 500 mesh or 0.028mm powder and granules, and liquid materials can be filtered to 5 microns;

2. Equipped with a bouncing ball cleaning device, which can achieve the purpose of cleaning the screen by continuously hitting the screen without blocking the screen. For viscous and electrostatic materials, the ultrasonic cleaning device can be used.

3. Fully enclosed structure, no dust spillage, improve the working environment;

4. It can screen 1 to 5 layers of screen mesh, and can carry out 2 to 6 grades of sorting or filtration at the same time;

5. Impurities and coarse materials are automatically discharged, continuous operation is possible, the discharge port can be rotated 360°, and the operation is convenient.

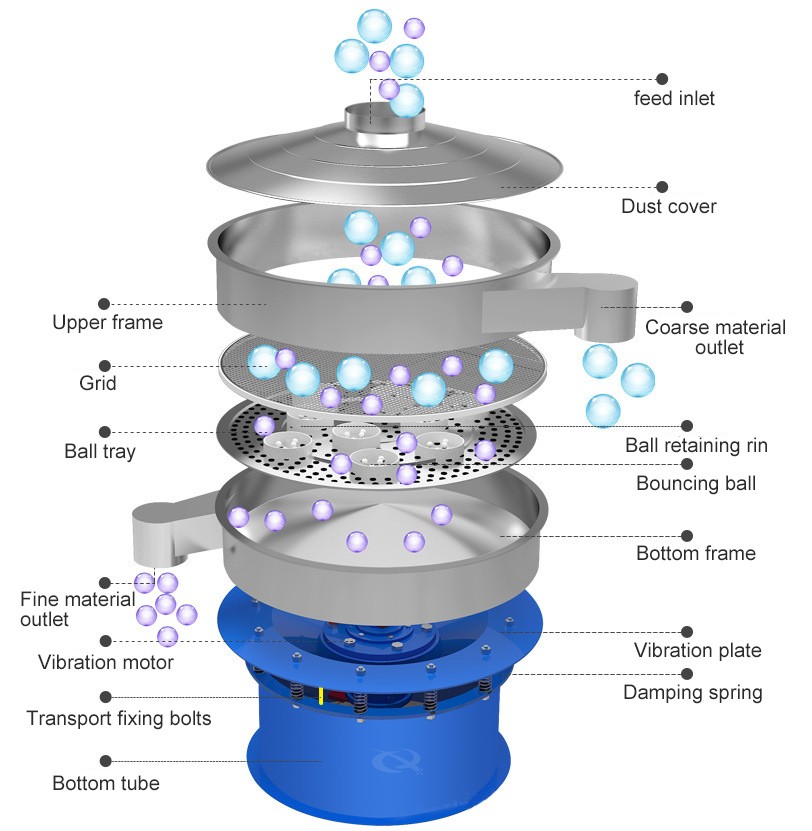

Industrial Sifter uses the YZUL vertical vibration motor as the excitation source, and converts the rotary motion into horizontal, vertical and inclined three-dimensional motion through the eccentric weights at the upper and lower ends of the vibration motor, and transmits it to the screen surface of the rotary vibrating screen; the material passes through The feeding port enters the equipment. According to different material screening requirements, the material is sieved by the screen. During this process, the net cleaning device under the screen - the bouncing ball continuously hits the screen, so that the upper layer of the screen can be removed. Smooth through mesh screening, and effectively solve the problem of material blocking the mesh, the sieve material and the sieve material are discharged from different discharge ports, so as to achieve the purpose of screening and removing impurities or filtering and grading.

| model | Sieve Diameter (mm) | Power (kw) | Grain size (mm) | Voltage (V) | Price ($/unit) |

| DH-400 | 350 | 0.18 | <10 | 380 | $400.00-$550.00 |

| DH-600 | 550 | 0.25 | $584.00-$830.00 | ||

| DH-800 | 750 | 0.55 | $690.00-$1,000.00 | ||

| DH-1000 | 920 | 0.75 | $970.00-$1,40000 | ||

| DH-1200 | 1120 | 1.1 | $1,300.00-$1,900.00 | ||

| DH-1500 | 1420 | 1.5 | $1,800.00-$2,600.00 | ||

| DH-1800 | 1720 | 2.2 | $2,300.00-$3,700.00 |

The rotary vibrating screen is mainly composed of feeding port, dust cover, discharging port, beam ring, screen, counterweight, upper weight, vibrating body, vibration motor, spring, lower weight, machine base and so on.