Focus Sifter Machine Production

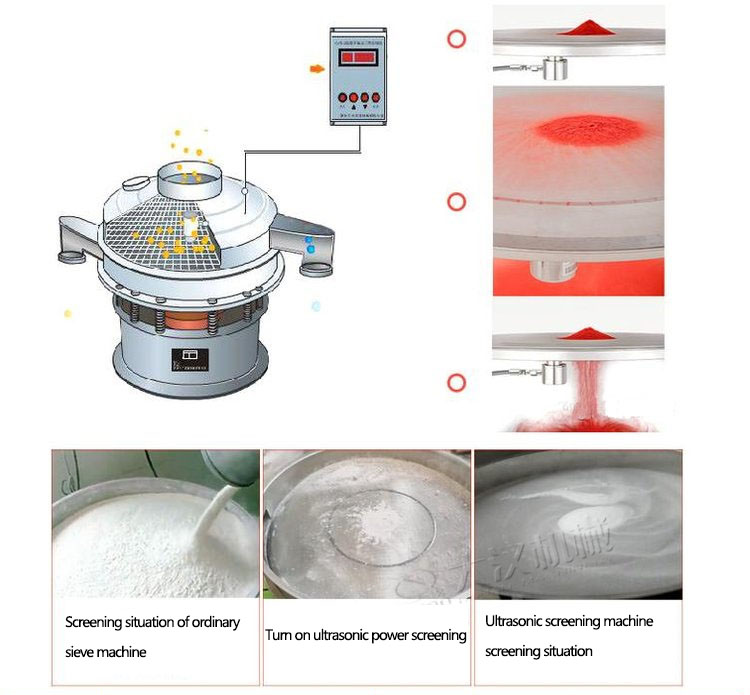

Ultrasonic sieving machine plus ultrasonic screening system to solve the screen blockage, automatic screen clearing, can screen ultra-fine powder materials, material permeability rate increased by 50%-400%, output increased by 10 times, screening accuracy of 99%.

Price: $700.00-$2,000.00/Set

Screening mesh: 80-600 mesh Output: 5 t/h

Model: 400mm-2000mm Level: 1-5 layers

Applicable materials: Flour, graphite powder, glass frit, metal powder, alloy powder and other fine powders

Product Type: Transducer Installation: Built-in (non-polluting, dedicated for food and pharmaceutical industries), external (easy to replace)

Ultrasonic Sieving Machine is an ultrasonic screening system installed on the basis of ordinary Sieving Machine. The purpose is to prevent mesh clogging and solve difficult screening of powdery materials such as strong adsorption, easy agglomeration, high static electricity, high fineness, and light specific gravity. For problems, the material penetration rate can be increased by 50%-400%, the output can be increased by 0.5-10 times, and the screening accuracy can reach 95%. Under the same sieve surface, the output of the ultrasonic sieving machine is 10 times higher than that of the ordinary sieving machine, and the sieving range can reach 20µm.

Solve the blocking of the screen: the screen frame runs three-dimensionally under the action of the vibration motor and superimposes the high-frequency and low-amplitude ultrasonic vibration, so that the material is suspended on the screen surface at a low altitude, thereby effectively solving the problem of the blocking of the material.

Secondary crushing: some materials will cause problems for the troupe when they are damp or friction generated static electricity. Under the action of ultrasonic waves, the aggregated materials can be secondary crushed, thereby increasing the output.

Light specific gravity screening: When ordinary vibrating screen screens light specific gravity materials, it is prone to material spillage and the screening accuracy cannot be achieved. Ultrasonic sieving machine can effectively improve screening accuracy and reduce dust spillage under the action of ultrasonic waves.

ultrasonic sieving machine for glass frit

Screen mesh: 20um

Output: 300kg/hour

Recommended model: DHC-400

ultrasonic sieving machine for metal powder

Screen mesh: 300 mesh, 400 mesh

Output: 1 ton/hour

Recommended model: DHC-800-2s

ultrasonic sieving machine for graphite powder

Screen mesh: 300 mesh

Output: 8 ton/hour

Recommended model: DHC-1500-2s

Ultrasonic sieving machine can sieve fine powders with strong adsorption, easy agglomeration, high static electricity, high fineness, high density and light specific gravity within 600 meshes. The specific materials are: flour, tapioca starch, API powder, washing powder, graphite powder, Nanomaterials, copper chloride powder, plastic powder, sulfur powder, micro-mineral powder, silicon carbide, alloy powder, molybdenum powder, stainless steel powder, tungsten powder, nickel powder, cobalt powder, powder coating, quartz powder, butamidone powder, Malt powder, ribavirin, coffee powder, electromagnetic powder, lithium battery material, negative electrode material, laser powder, etc.

Screening Powder Coatings

mesh:160 mesh, 180 mesh, 200 mesh

output:500kg/hour

recommend:DHC-800 type

flour sieving

mesh:140 mesh

output:400kg/hour

recommend:DHC-600 type<

sifted chili powder

mesh:60 mesh

output:1 ton/hour

recommend:DHC-1200 type

Sieving pills/powders (caking, damp)

mesh:300 mesh

output:2 tons/hour

recommend:DHC400 type (stainless steel)

Sieve copper chloride powder

mesh:150 mesh, 400 mesh

output:1-2 tons/hour

recommend:DHC-1200 type<

Sift heavy calcium powder

mesh:80-300 mesh

output:10 ton/hour

recommend:DHC-1800-2s

| Material picture | Material | Material characteristics | mesh | Recommended model | Output | Advantages of Using Ultrasonic Sieving Machine |

|

Silicon carbide | High hardness, small expansion coefficient, brittleness, good thermal conductivity, etc. | 200 mesh | DHC-1200 (2 layers) | 3 tons/hour | The impact force and vibration force are small, which can prevent the silicon carbide from being damaged by the vibration ability during the screening process. |

|

wood flour | Light specific gravity, fluffy, easy to cake | 270 mesh | DHC-1000 | 2 tons/hour | High frequency vibration suppresses clumping and fluffing issues. |

|

Lithium battery material | Good electrical conductivity and classic resistance, light weight, poor flow, high viscosity, low yield | 100 mesh,300 mesh | 200-300kg | DHC-1500 | It can solve the problems of powder specific gravity, low material fluidity, high viscosity and low screening output |

|

Chinese medicine powder | Light specific gravity, easy to agglomerate, easy to stick | 200 mesh | DHC-800 | 700kg/hour | Fully sealed screening method, high-frequency screening can solve screening problems such as small particle size, light weight, easy suspension, etc. |

|

epoxy powder | Thermoset Powder Coatings with Corrosion Resistance and Toughness | 60 mesh, 80 mesh | DHC-600 | 400 kg/h | Solve the problem of low specific gravity of powder, corrosion resistance and prolong service life |

|

Nickel Ternary Cathode Materials | Low cost, poor material flow, high viscosity, low output | 300 mesh | DHC-600 | 300 kg/h | Solve the problems of poor material fluidity, high viscosity, low yield and low screening |

|

Sulphur powder | Combustible, sterilization, laxative, easy to agglomerate. | 100 mesh | DHC-400 | 400 kg/h | Solve the problems of low powder specific gravity, external corrosion resistance and long service life |

|

graphite powder | Strong stickiness and oiliness | 50 mesh, 80 mesh, 100 mesh | DHC-1500-3s | 5 tons/hour | It can break up the lumps and solve the screening problems such as strong viscosity, high static electricity and ultra-fine powder. |

|

coating | Light viscosity, agglomerates into particles, sometimes dusty, wastes raw materials and pollutes the environment | 450 mesh | DHC-1200-2s | 300 kg/h | Fully enclosed screening structure to solve the screening problem of lightly viscous and agglomerated particles |

Ultrasonic sieving machine due to the installation of ultrasonic screening system, the frequency of vibration can reach 36,000 times per second, suitable for 80-600 mesh separation powder, especially for difficult to screen materials The effect is remarkable, the output can be increased by 0.5-10 times.

Comparison of sieving effect between Ultrasonic Sieving Machine and ordinary sieving machine

| Model | Test material | Ordinary Sieving Machine | Ultrasonic Sieving Machine | ||

| Mesh | Test Results | Mesh | Test Results | ||

| φ1000 | Silicon carbide | 500 | cannot be sieved | 500 | 1000kg/h |

| Tungsten carbide powder | 600 | 15 minutes without sifting out fine powder | 600 | 30kg/h | |

| Vitamin C Powder | 100 | 1kg/h | 100 | 120-150kg/h | |

| φ600 | pollen | 400 | 15 minutes without sifting out fine powder | 400 | About 20% fine powder is sieved in 15 minutes, and finer grading is possible |

| φ1000 | Nickel, Zinc, Cobalt Powder | 325 | 10kg/h | 400 | 300kg/h |

| Emery powder | 400 | Cannot be sieved | 300 | 13000kg/h | |

| φ1000 | clay | 60 | 1055kg/h | 60 | 2232kg/h |

| 100 | 288kg/h | 100 | 618kg/h | ||

| φ800 | glass powder | 100 | Cannot be sieved | 100 | 40kg/h |

| φ800 | Microsilica | 500 | Cannot be sieved | 500 | 97kg/h |

| φ600 | Pigment powder | 200 | Cannot be sieved | 200 | 300kg/h |

Built-in Ultrasonic Sieving Machine: The transducer is installed at the bottom of the screen (the screen frame and screen need to be removed during installation), suitable for use in the food and pharmaceutical industries, avoiding cross-contamination, and the price is cheap.

External Ultrasonic Sieving Machine: The transducer is installed outside the screen frame and does not come into contact with the material. It can screen corrosive materials and is expensive.

The Ultrasonic Sieving Machine material is available in carbon and stainless steel.

Carbon steel Ultrasonic Sieving Machine: used for sieving of common powdery materials.

Stainless steel Ultrasonic Sieving Machine: used for powdery materials with hygienic requirements, such as: flour, milk powder, starch, medicine powder and other food/pharmaceutical industries.

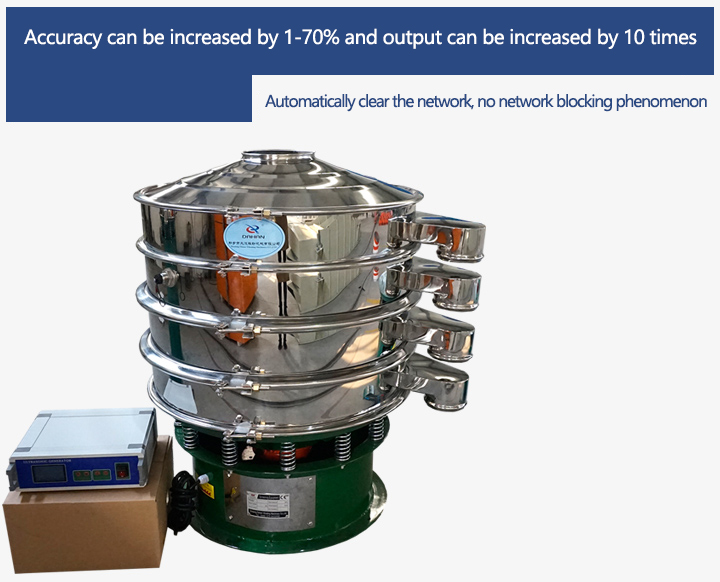

Ultrasonic sieving machine improves the sliding effect of low-density powder in gravity settling (light contact between the powder and the mesh port), the retention or wedging of high-density metal at the mesh port, and the adhesion effect of electrostatic powder, thereby improving the sieving effect. Separation efficiency and screening quality. Compared with the ordinary rotary vibrating screen, the ultrasonic sieving machine's precision is increased by 1-70%, the output is increased by 0.5-10 times, the material passing rate is increased by 50%-400%, and the screening efficiency can reach 99%.

Ultrafine powder sieving (screening 25µm powder, filtering 10µm liquid)

The ultrasonic system solves the problems of strong adsorption, static electricity, strong viscosity, high density and other ultrafine powder screening.

High screening yield

Compared with ordinary Sieving Machine, the screening accuracy is increased by 1-70%, and the output can be increased by 0.5-10 times.

Not easy to block the network

The vibration frequency is 36,000 times/min, the passing rate of the screen surface increases by 50%-400%, and the number of repeated screen passes is reduced

No dust pollution

The fully enclosed structure can change the pollution caused by the conventional screening method to the powder and reduce the noise.

Ultrasonic sieving machine converts 220V, 50Hz or 110V, 60Hz electric energy into 18~40KHz high-frequency electric energy, through ultrasonic power supply, input ultrasonic cleaning mesh transducer, and convert into mechanical 18~40KHz wave, these fluctuations will be transmitted to The pre-adjusted rod-shaped resonator is then uniformly transmitted to the screen surface of the vibrating screen, so that the ultra-fine powder is subjected to huge ultrasonic acceleration, thereby inhibiting clogging and improving the screening and cleaning efficiency, so as to achieve high-efficiency screening and net cleaning. Purpose.

| Model | Diameter mm | Screen area m2 | Screen specification (mesh) | Feeding granularity mm | Vibration time rpm | Recommended price |

| DH-600 | Φ600 | 0.24 | 2-500 | <Φ10 | 1500 | $400.00-$840.00 |

| DH-800 | Φ800 | 0.45 | 2-500 | <Φ15 | 1500 | $700.00-$1340.00 |

| DH-1000 | Φ1000 | 0.67 | 2-500 | <Φ20 | 1500 | $800.00-$1500.00 |

| DH-1200 | Φ1200 | 1.0 | 2-500 | <Φ30 | 1500 | $1000.00-$2100.00 |

| DH-1500 | Φ1500 | 1.6 | 2-500 | <Φ30 | 1500 | $1200.00-$2700.00 |

| DH-1800 | Φ1800 | 2.43 | 2-500 | <Φ30 | 1500 | $1700.00-$3700.00 |

| DH-2000 | Φ2000 | 3.01 | 2-500 | <Φ30 | 1500 | $2100.00-$5000.00 |

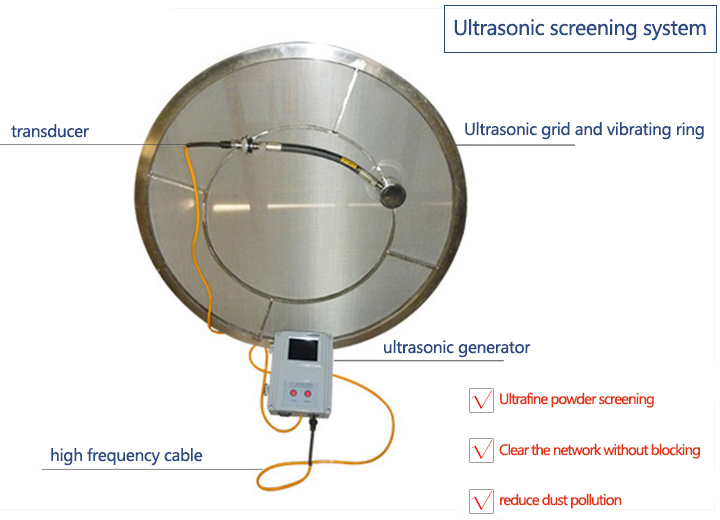

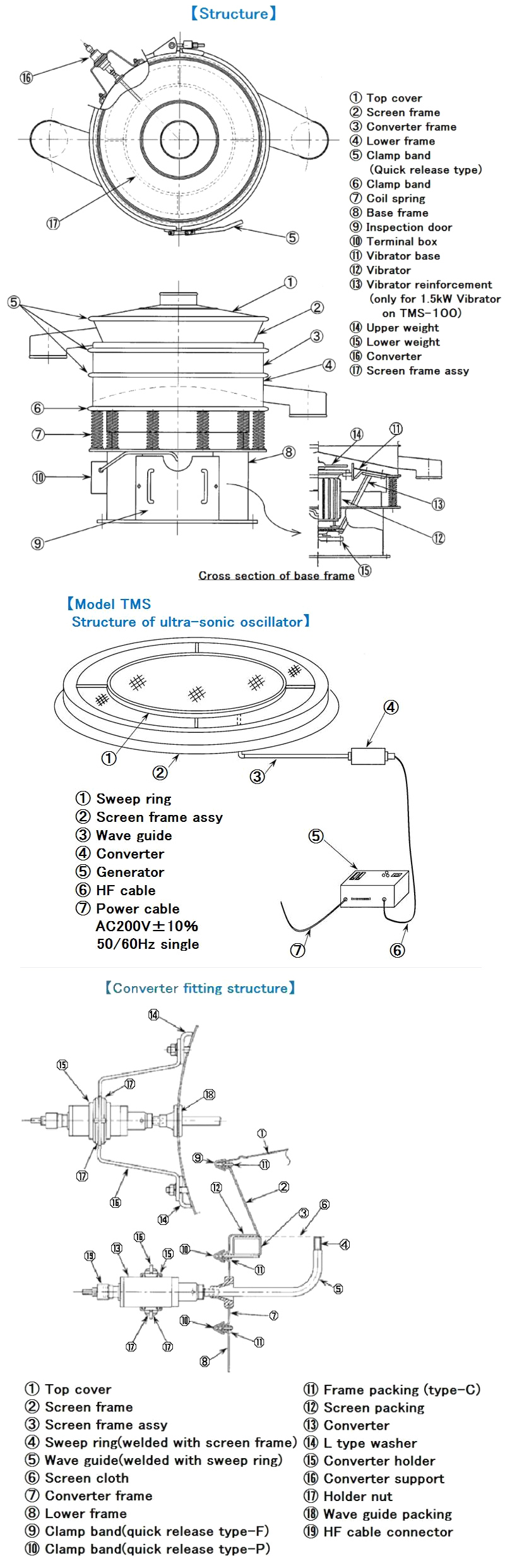

Ultrasonic Sieving Machine is composed of feed inlet, dust cover, ultrasonic power supply, transducer, screen, grid frame, vibration motor, shock absorbing spring, vibration motor, discharge outlet, beam ring, base and other parts.

Ultrasonic resonant power supply: high-frequency and high-power ultrasonic resonant power generator, using digital frequency modulation amplitude modulation, can automatically track the resonance point according to different states of screening (different material grid structure), to maximize power output, long-term stable work, small heat generation, easy to use.

High-frequency cable: Cable connection is used between the ultrasonic generator and the ultrasonic transducer.

Connector interface: aviation plug.

Transducer: High-performance ultrasonic converter with sealed structure to prevent micropowder from entering.

Ultrasonic grid frame: It is composed of an external grid frame and a resonance ring.

Screen: suitable for 10 mesh --- 635 mesh.

Dahan Ultrasonic Sieving Machine manufacturers produce ultrasonic vibrating sieve, Ultrasonic vibrating sieving machine, built-in Ultrasonic Sieving Machine, external Ultrasonic Sieving Machine, stainless steel Ultrasonic Sieving Machine, pharmaceutical Ultrasonic Sieving Machine, powder Ultrasonic Sieving Machine, rubber powder Ultrasonic Sieving Machine, starch Ultrasonic Sieving Machine, Coating Ultrasonic Sieving Machine, Metal Powder Ultrasonic Sieving Machine, Graphite Powder Ultrasonic Sieving Machine, Glass Powder Ultrasonic Sieving Machine, Explosion-proof Ultrasonic Sieving Machine and other products. Diameter 400-1800mm, layers 1-5 are optional; materials are carbon steel, stainless steel, transducer can be built-in or external; dedicated to sieving graphite powder, diamond, glass powder, silicon-aluminum powder, oxidation within 600 mesh Aluminum, metal powder, fluorescent powder, catalyst, chili powder, matcha powder and other fine powders; in addition, customized products can also be made according to user needs (use purpose, scene, material), such as mobile type, heightened bottom bucket, sieve High frame price type, gate type, edge type, etc.

Determine material properties

Processing raw materials: name, particle size structure, specific gravity, moisture content, temperature, etc.

Purpose of usage

Ultrasonic Sieving Machine can remove impurities, classify, filter, select multiple layers for screening (2-5 layers of screens, screen out 3-6 different specifications), and select single layer for impurity removal and filtration

Processing capacity

Ultrasonic output can reach 5 tons, and relevant models can be selected according to the output (DHC-400-DHC-1800)

Customized product

Provide materials, use site, output and other information for customization, such as: control screening time - gate type ultrasonic sieving machine, flammable and explosive materials - explosion-proof ultrasonic sieving machine