Focus Sifter Machine Production

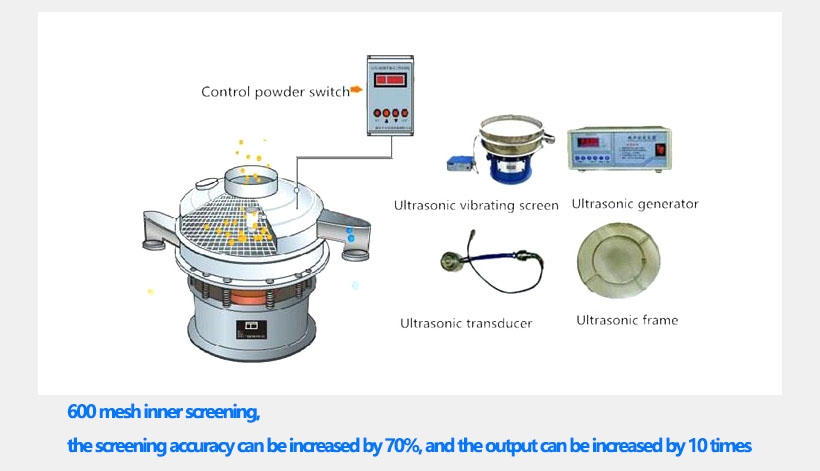

1. Ultrasonic transducer: It is the characteristic structure of ultrasonic sieving machine, which has the function of converting low-frequency electric energy into high-frequency and low-amplitude ultrasonic waves.

2. Ultrasonic special grid: This grid structure is equipped with a resonance ring, which converts ultrasonic waves into mechanical waves with high vibration frequency and low amplitude, and then transmits them to the surface of the screen.

3. Ultrasonic power supply: This structure controls the output power and frequency of ultrasonic waves and can be adjusted.

4. Screen mesh, screen frame, vibration exciter, base: The screen mesh is of woven type, and the structure of the screen frame, vibration exciter, base and ordinary vibrating screen is similar.

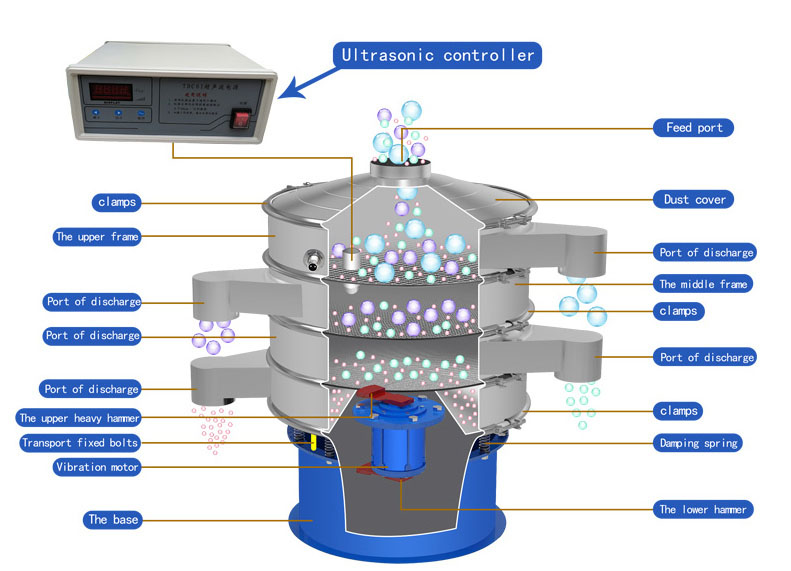

1. Low-amplitude vibration reduces the vibration height of the material, maintains the contact between the material and the screen surface, and reduces the phenomenon of empty material.

2. It can be used in single-layer and multi-layer, and a set of intelligent ultrasonic generator uses three transducers at the same time.

3. Solve the screening problems such as strong adsorption, easy agglomeration, high static electricity, high precision, high density and light specific gravity.

4. The secondary crushing makes the materials that are easy to agglomerate loose again, which improves the screening efficiency.