Focus Sifter Machine Production

Commercial flour sifter can be used for flour grading and removal in flour mills and flour production lines.

Price:$800.00-$4,500.00/Set

output:100-5000kg/h

Screen specification: 2 - 500 mesh

Diameter:400-2000mm

Layer(s) : 1 - 5 (Recommended 3)

Material: 304 stainless steel/316L stainless steel

Materials: Flour, Breadcrumbs, Corn Flour, Wheat Flour, Starch.

Commercial flour sifter is equipment used in flour mills to screen and remove lumps, foreign matter and contaminants. It can be used for sieving various types of flour within 500 mesh, such as: wheat flour, semolina, corn flour and other food processing plants and flour production lines. 1-5 layers of sieves can be used, and the flour can be sieved into 2-6 different fineness. The whole machine is made of 304/316L stainless steel, which is clean, hygienic, easy to clean, and conforms to food hygiene standards.

impurity removal of flour

Ultrasonic system for screening flour

flour sieving

Commercial flour sifter can be used in small artisanal bakeries, large industrial flour mills, flour production lines, etc. to remove contaminants and lumps in food production lines, sifting any type of flour including hard and soft wheat flour, semolina, corn Flour, starch, rice flour, whole milk powder, soybean flour and other materials.

| materials | Way of working | Screen (mesh/inch) | Handling capacity (kg/hour) | model |

| milk powder | dry | 16-20 | 2000 | DH-1200-1S |

| starch | dry | 80 | 1200 | DH-2000-2S |

| wheat starch | Wet | 200 | 3200 | DH-2000-1S |

| flour | dry | 24 | 1500 | DH-1000-1S |

| Glucose powder | dry | 6,20 | 2000 | DH-1200-2S |

| Rice flour | dry | 100 | 300 | DH-1000-1S |

| Skim milk powder | dry | 24 | 3000 | DH-1200-1S |

| Whole milk powder | dry | 12 | DH-1000-1S | 1600 |

| Corn flour | dry | 40 | DH-1000-1S | 1600 |

Commercial flour sifter generally uses a 40-mesh sieve for sifting flour, and a 40-60-mesh sieve for household flour sifting. Use a 60-90 mesh sieve for the flour used in cake desserts, and the flour needs to be sieved finer. Dahan commercial flour sieve can sieve all kinds of flour within 500 mesh, you can choose according to your needs.

| state of flour | Mesh size | Output (kg/h) |

| dry | 20 mesh (0.8mm) | 2000 |

| dry | 30 mesh (0.55mm), 45 mesh (0.18mm) | 1500 |

| dry | 80 mesh (0.18mm) | 1200 |

Flour passes through screens of different meshes

| Number of meshes (mesh) | 24 | 50 | 60 | 80 | 120 |

| Pass content (g) | 9.72 | 9.31 | 8.92 | 8.64 | 7.43 |

| Fail content (g) | 0.28 | 0.69 | 1.08 | 1.36 | 2.57 |

| By percentage (%) | 97.2 | 93.1 | 89.2 | 86.4 | 74.3 |

Material: Commercial flour sifter is made of stainless steel, all stainless steel

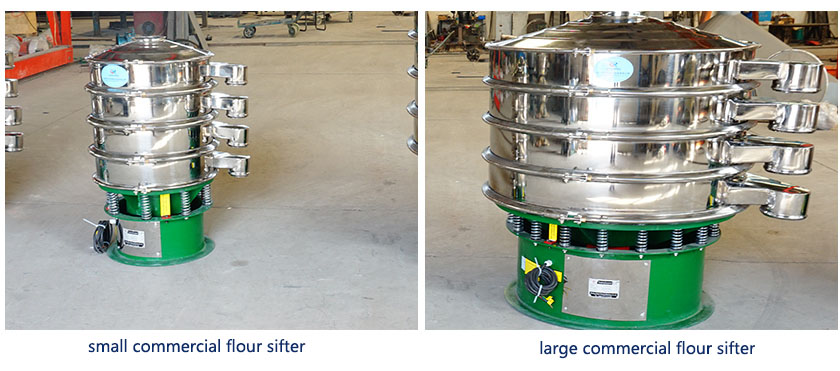

Model: Commercial flour sieve models include 400mm, 600mm, 800mm, 1000mm, 1500mm, 1800m, 2000mm, etc.; the corresponding output is 1-5 tons/hour, and the sieving model determines the output; users with small output recommend 400mm, 600mm, 800mm, etc. Small commercial flour sieves, users with large output requirements recommend large commercial flour sieves such as 1500mm, 1800m, and 2000mm.

Hierarchy: Commercial flour sieve has 1-5 layers optional, single-layer sieve is used for flour removal, multi-layer sieve is used for flour coarse classification;

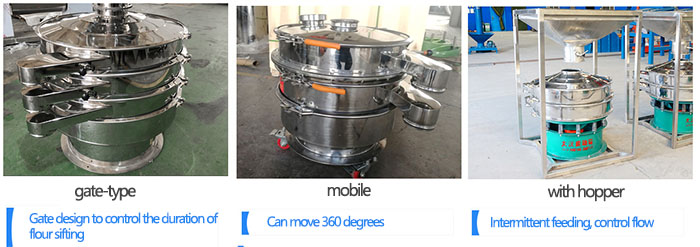

Customization: Commercial flour sifter can be specially customized according to material properties, such as: gate-type Commercial flour sifter (can control the duration of flour sifting), mobile Commercial flour sifter (with universal wheels at the bottom, free direction control), explosion-proof Commercial flour sifter (dust explosion-proof).

1. The commercial flour sieve is made of SUS304 or 316L stainless steel, mirror polished, and the internal and external surface finish is 0.1-0.2RA, which meets the hygienic requirements and safety standards of the food industry.

2. Flour can be sifted to 500 mesh or 0.028mm, and the fineness and precision of flour can reach 98%.

3. Commercial flour sifter has 1-5 layers, which can sieve flour into 2-6 different fineness.

4. The fully enclosed structure prevents the flour from flying, eliminates the problem of dust in the air, and has no pollution from manual interaction.

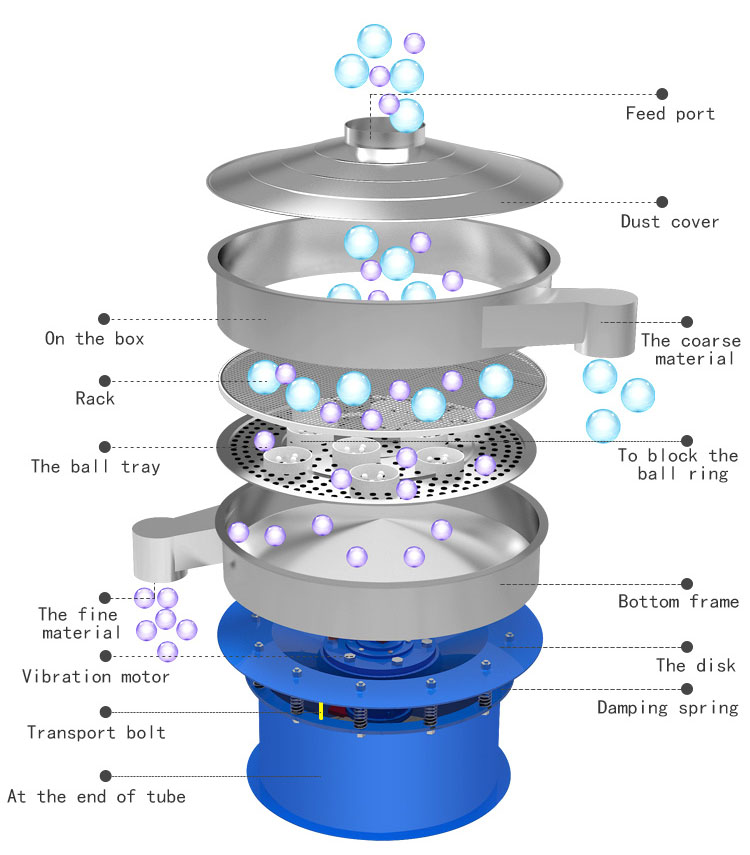

When the commercial flour sifter is working, when the flour is poured into the sieve from the feeding port, the vertical vibration motor is used as the power source to make the flour move horizontally, vertically or inclined three-dimensionally on the sieve surface. During the sieving process, the flour spreads continuously from the middle to the surrounding areas. According to the requirements of the sieving mesh, the flour larger than the aperture of the sieve is discharged from the discharge port of this layer. The flour that is smaller than the aperture of the screen is sieved, and enters the next layer of screen to continue screening until it is discharged from the discharge port to complete the screening.

| model | Sieve Diameter (mm) | Power (kw) | Grain size (mm) | Voltage (V) | Price ($/unit) |

| DH-400 | 350 | 0.18 | <10 | 380 | $400.00-$550.00 |

| DH-600 | 550 | 0.25 | $584.00-$830.00 | ||

| DH-800 | 750 | 0.55 | $690.00-$1,000.00 | ||

| DH-1000 | 920 | 0.75 | $970.00-$1,40000 | ||

| DH-1200 | 1120 | 1.1 | $1,300.00-$1,900.00 | ||

| DH-1500 | 1420 | 1.5 | $1,800.00-$2,600.00 | ||

| DH-1800 | 1720 | 2.2 | $2,300.00-$3,700.00 |

Commercial flour sieve is mainly composed of feed inlet, dust cover, discharge outlet, beam ring, screen, counterweight, upper weight, vibrating body, vibration motor, spring, lower weight, machine base and other parts.

Dust-proof cover: prevent the material from spreading outward, and also protect the external dust from entering, thereby polluting the screened material.

Brace ring: used to fix the screen frame part in the middle of the screen body.

Upper heavy hammer, lower heavy hammer: Changing the phase angle of the upper and lower heavy hammers of the vibrating motor motor can change the trajectory and residence time of materials on the screen.

Spring: Vibration and sound insulation.

Frame: support the entire vibrating screen and keep it working stably.

Dahan Commercial flour sifter manufacturer produces Commercial flour sifter, large commercial flour sifter, small commercial flour sifter, ultrasonic commercial flour sifter, stainless steel commercial flour sifter, industrial commercial flour sifter, gate commercial flour sifter, electric commercial flour sifter, heightened screen frame Commercial flour sifter and other equipment, the models are 400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm, etc.; the material is 304 or 316L stainless steel, according to different mesh numbers and application places, our factory supports customized products.