Focus Sifter Machine Production

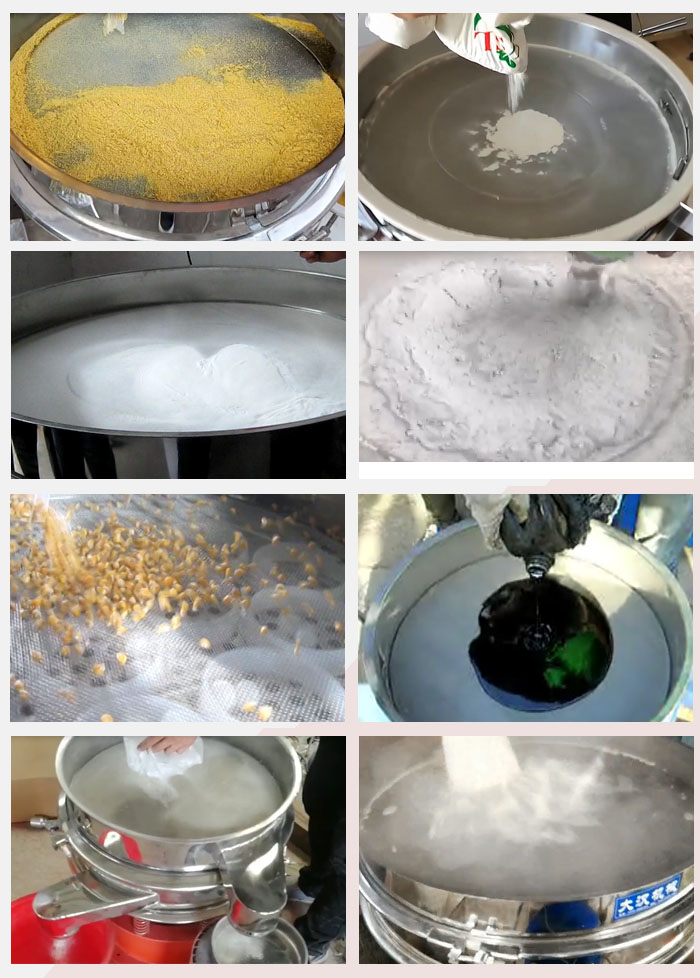

Vibrating Sieve is mainly used for impurity removal, classification and filtration of powder, granular and slurry materials. It has a fully enclosed structure, low noise and no dust pollution. Carbon steel, stainless steel, plastic and other materials can be selected according to the screening materials.

| product | Vibrating Sieve | price | $500-$4500 |

| mesh | 500 mesh | output | 1-5 t/h |

| use | sieve, filter, remove impurities | materials | powder, granule, liquid |

| material | Carbon Steel, Stainless Steel, Plastic | Hierarchy | 1-6 layers |

| custom made | Mobile type, gate type, edge type, ultrasonic type, explosion-proof type, screen frame heightened type, etc. | ||

Vibrating Sieve is mainly used for screening powder, granule and liquid materials in various industries. It has high screening accuracy and can realize multi-level control.

Chemical industry: resins, coatings, industrial drugs, cosmetics, paints, traditional Chinese medicine powder, etc.

Food industry: powdered sugar, starch, salt, rice flour, milk powder, soy milk, egg powder, soy sauce, fruit juice, etc.

Metal, metallurgy and mining: aluminum powder, lead powder, copper powder, ore, alloy powder, electrode powder, manganese dioxide, electrolytic copper powder, electromagnetic material, grinding powder, refractory material, kaolin, lime, alumina, heavy carbonic acid Calcium, quartz sand, etc.

Pollution treatment: waste oil, waste water, dyeing and finishing waste water, auxiliaries, activated carbon, etc.

1. No blocking net: the bouncing ball net cleaning device can clean the screen surface and reduce the loss caused by blocking the net;

2. High-efficiency screening: Flange motor is used, with large power, high screening efficiency and low noise;

3. No dust pollution: fully enclosed structure, no dust pollution, no liquid spillage;

4. Large output and strong degree of automation: impurities and coarse materials are automatically discharged, and the screening output can reach 5 tons/hour;

5. Wide range of materials: a wide range of screening materials, which can screen particles as fine as 500 mesh or 0.028mm, and filter 500 mesh slurry;

Vibrating Sieve uses a vertical vibration motor as the excitation source. The eccentric weights at the upper and lower ends of the motor convert the rotary motion into horizontal, vertical and inclined three-dimensional motion, and transmit it to the screen surface; the material enters the equipment through the feeding port. , According to different screening requirements, the material passes through 1-5 layers of sieves with different meshes. During this process, the screen cleaning devices located under the screens of each layer continuously hit the screen, so that the material can be smoothly It can effectively screen and effectively avoid the problem of material blocking.