Focus Sifter Machine Production

Ultrasonic Vibrating Screen can effectively solve the screening problems such as blocking, sticking, adsorption, high static electricity and light specific gravity of materials in the screening process. The high efficiency of screening is inseparable from the selection of Ultrasonic Vibrating Screen, then How to choose Ultrasonic Vibrating Screen?

Before introducing the Ultrasonic Vibrating Screen selection, let's introduce the model:

The main models are DHC400, DHC600, DHC800, DHC1000, DHC1200, DHC1500, DHC1800. Different models have different processing capacity.

| Model | Diameter mm | Screen area m2 | Screen specification (mesh) | Feeding granularity mm | Vibration time rpm | Recommended price |

| DH-600 | Φ600 | 0.24 | 2-500 | <Φ10 | 1500 | $400.00-$840.00 |

| DH-800 | Φ800 | 0.45 | 2-500 | <Φ15 | 1500 | $700.00-$1340.00 |

| DH-1000 | Φ1000 | 0.67 | 2-500 | <Φ20 | 1500 | $800.00-$1500.00 |

| DH-1200 | Φ1200 | 1.0 | 2-500 | <Φ30 | 1500 | $1000.00-$2100.00 |

| DH-1500 | Φ1500 | 1.6 | 2-500 | <Φ30 | 1500 | $1200.00-$2700.00 |

| DH-1800 | Φ1800 | 2.43 | 2-500 | <Φ30 | 1500 | $1700.00-$3700.00 |

| DH-2000 | Φ2000 | 3.01 | 2-500 | <Φ30 | 1500 | $2100.00-$5000.00 |

Material is the core of determining the selection of Ultrasonic Vibrating Screen. Ultrasonic Vibrating Screen is mainly for high-fine powder materials or materials that are easy to block. It can screen dry powdery materials within 80-600 mesh, or suitable for screening of materials with strong adsorption, easy agglomeration, viscosity, high static electricity, high density, light specific gravity, materials below 300 mesh Linear vibrating screen or rotary vibrating screen can be selected.

Secondly, the characteristics of the screening materials also directly affect the selection of Ultrasonic Vibrating Screen materials, and also have a certain impact on the selection. The other parts are made of ordinary carbon steel, and the other is made of 304 stainless steel for the whole machine (food, medicine and other fields that require hygiene).

The purpose of selection is to achieve production capacity, and the output is determined by the diameter of the screen surface and the effective screen surface area, so it is necessary to confirm the output requirements in order to determine the size of the equipment. In order to meet the needs of fine screening in various industries as much as possible, Dahan Ultrasonic Vibrating Screen has a variety of models for users to choose from. Different models correspond to different screening areas, screening efficiency and processing capacity. These factors are directly related to the main output. standard. Therefore, users should make reasonable choices according to the needs of screening output when purchasing. However, due to the difference in water content, particle size and adhesion of different materials, the equipment of the same model may have a great difference in processing capacity. Therefore, it is recommended that you communicate with professional manufacturers when purchasing to determine the appropriate Ultrasonic Vibrating Screen model.

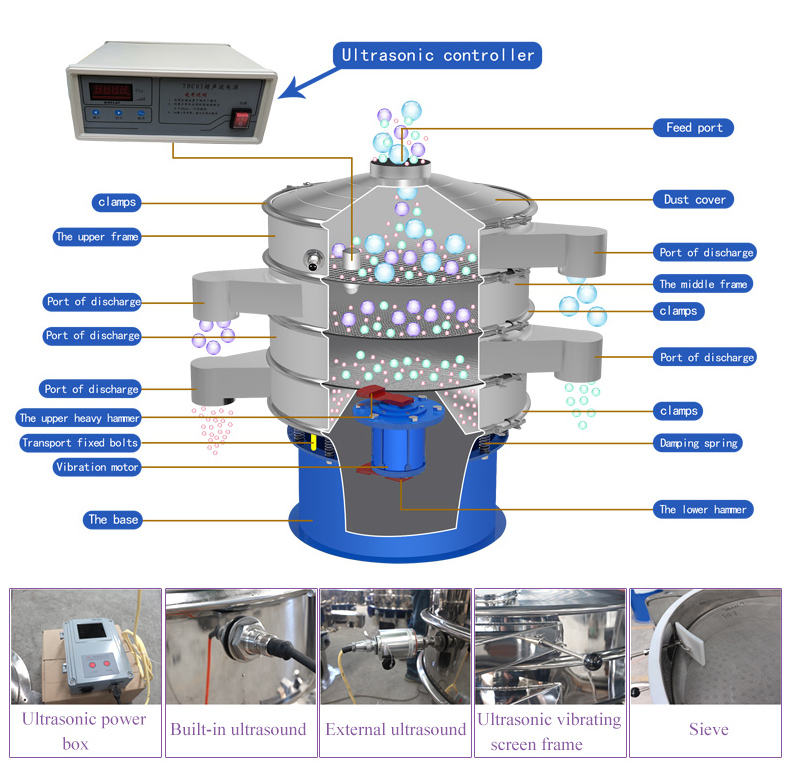

Ultrasonic Vibrating Screen is mainly composed of dust cover, transducer, vibrating body, vibration damping spring, ultrasonic power supply, base and other parts. The choice of accessories directly affects the working efficiency and service life of the Ultrasonic Vibrating Screen.

Taking the vibration motor as an example, the importance of the selection of the vibration motor as the power source of the vibrating screen equipment can be imagined. The vibrating screen vibration motor usually chooses YZUL vertical vibration motor. In addition, you can choose the appropriate excitation force size and series in this motor type according to your own output. The Ultrasonic Vibrating Screen motor of some manufacturers uses inferior aluminum wire instead of copper. Line, continuous failures in use, increase user maintenance costs, resulting in user economic losses.

There are still many factors that need to be considered when selecting the Ultrasonic Vibrating Screen, but in the final analysis, it is still under the premise of ensuring the quality of the screening machine to provide users with Ultrasonic Vibrating Screen with more efficient screening and reasonable price. Xinxiang Dahan Vibration Machinery Co., Ltd. As a direct-selling vibrating screen manufacturer, the Ultrasonic Vibrating Screen produced by it is of excellent quality, transparent price, complete models, customized on demand, 1-year warranty period, free maintenance, and worry-free after-sales.