Focus Sifter Machine Production

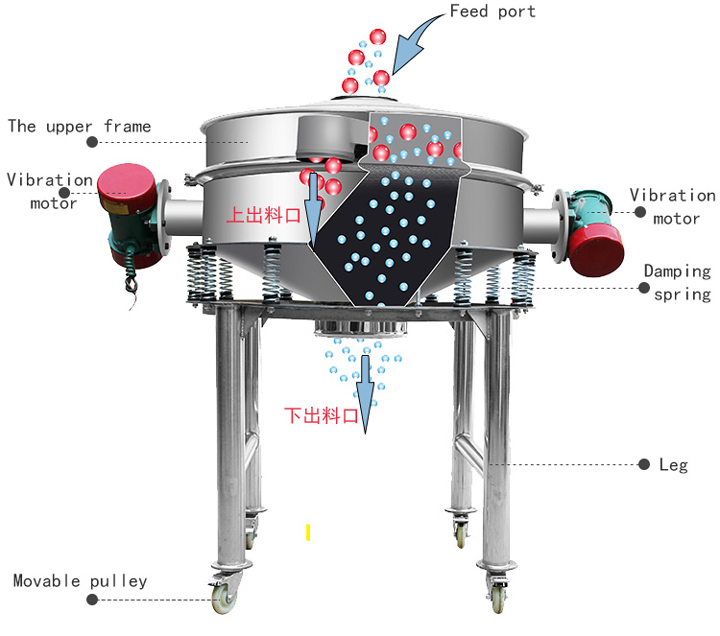

Stainless Steel Inline Vibro Sifter is a common screening equipment with a wide range of applications and important functions. Stainless Steel Inline Vibro Sifter is a device that uses linear vibration for screening. It is mainly composed of a vibration motor, a screen, a base and other parts. One of its characteristics is that it is made of stainless steel, which has the advantages of corrosion resistance, oxidation resistance, and easy cleaning. It is suitable for industries with high hygiene requirements. Stainless Steel Inline Vibro Sifter is suitable for screening various granular materials, such as powder, granules, and granular materials. It can be adjusted according to the characteristics and requirements of different materials to achieve precise screening and meet the production needs of different industries. Stainless Steel Inline Vibro Sifter has a simple structure, convenient operation, easy maintenance, stable working performance and long service life.

The work of Stainless Steel Inline Vibro Sifter is driven by a vibration motor. The vibration motor generates vibration force through the exciter, causing the entire screen machine to vibrate linearly, so that the granular material is screened on the screen. The screen of the stainless steel inline screen is usually composed of multiple layers of sieve holes with different particle sizes. When the granular material passes through the screen, it will pass through different sizes of sieve holes according to the size of the particles, so as to achieve the grading and screening of the particles. When the vibration motor is started, the screen machine begins to vibrate linearly, and the granular material is placed above the screen machine. As the vibration proceeds, the particles continue to move, collide, and separate in the sieve holes. Smaller particles fall into the container below through the sieve holes, while larger particles cannot pass through the sieve holes and remain above the sieve, so as to achieve the separation and screening of particles. The stainless steel inline screen can be screened at multiple levels as needed. Through the adjustment of different levels of sieves and vibration parameters, the particles can be accurately controlled and graded to meet the screening requirements of different granular materials. During the working process, the stainless steel inline screen needs to be cleaned and maintained regularly to ensure the smooth flow of the sieve and the normal operation of the equipment. Cleaning and maintenance work can extend the service life of the equipment and ensure the screening effect and production efficiency.

Stainless Steel Inline Vibro Sifter is widely used in the food industry for screening and grading of food raw materials, such as flour, starch, powdered sugar, seasonings, etc. It can help food production companies improve production efficiency, ensure product quality, and meet food hygiene and safety standards. In the pharmaceutical industry, stainless steel inline screens are often used for screening of pharmaceutical raw materials and grading of particles, such as powder and pill raw materials. It can help pharmaceutical companies achieve precise control of particle size and ensure drug quality and efficacy. Chemical raw materials and granular materials in the chemical industry often need to be screened. Stainless steel inline screens can meet the chemical companies' demand for precise screening of granular materials, improve production efficiency, and reduce production costs. In the building materials industry, stainless steel inline screens can be used for screening and grading of building materials such as cement, lime, and coal powder, which helps to improve the quality and stability of building materials products. In the metallurgical industry, stainless steel inline screens are often used for screening and grading of granular materials such as ores and metal powders, helping metallurgical companies improve production efficiency and optimize production processes. In the field of waste treatment and resource recycling, stainless steel inline screens also play an important role in screening and grading waste to achieve effective utilization and recycling of resources.

Wear-resistant and pressure-resistant: The screen material is strong and durable, with good wear resistance and pressure resistance, and can adapt to the screening needs of different granular materials.

Reliable and stable: The stainless steel inline screen has a simple structure, stable and reliable operation, convenient operation, easy maintenance, and reduces equipment failure and downtime.

Versatile application: The stainless steel inline screen has a wide range of applications and can be used for screening and grading of granular materials in many industries such as food, medicine, chemicals, and building materials.

Flexible adjustment: The vibration parameters of the stainless steel inline screen can be adjusted as needed to achieve precise control of the screening process and adapt to the screening requirements of different granular materials.

Stainless Steel Inline Vibro Sifter improves production efficiency and product quality, and also brings many economic and environmental benefits. The use of advanced stainless steel inline screens shows that the company pays attention to the upgrading of production technology, product quality and production efficiency, which helps to establish a good corporate image. The stainless steel inline screen reduces dust and noise in the production process, improves the working environment of employees, and improves the working comfort and production efficiency of employees. The stainless steel straight-discharge screen can accurately control the size and distribution of particles, ensure the uniformity and quality stability of the product, improve the quality level of the product, and enhance the competitiveness of the enterprise. It is an important production equipment that has a positive impact on the enterprise.